Feb 06, 2026

The report “Medical Equipment Cooling Market By Cooling Type (Air Cooling Systems, Liquid Cooling Systems, Thermoelectric Cooling Systems), By Equipment Type (Machine Learning, Computer Vision, Natural Language Processing, Predictive & Prescriptive Analytics), By Component (Compressor, Heat Exchanger, Fans & Blowers, Chillers & Cooling Units), By End-Users (Hospitals & Clinics, Diagnostic Centers, Ambulatory Surgical Centers, Research & Academic Institutions)” is expected to reach USD 4.90 billion by 2033, registering a CAGR of 12.90% from 2026 to 2033, according to a new report by Transpire Insight.

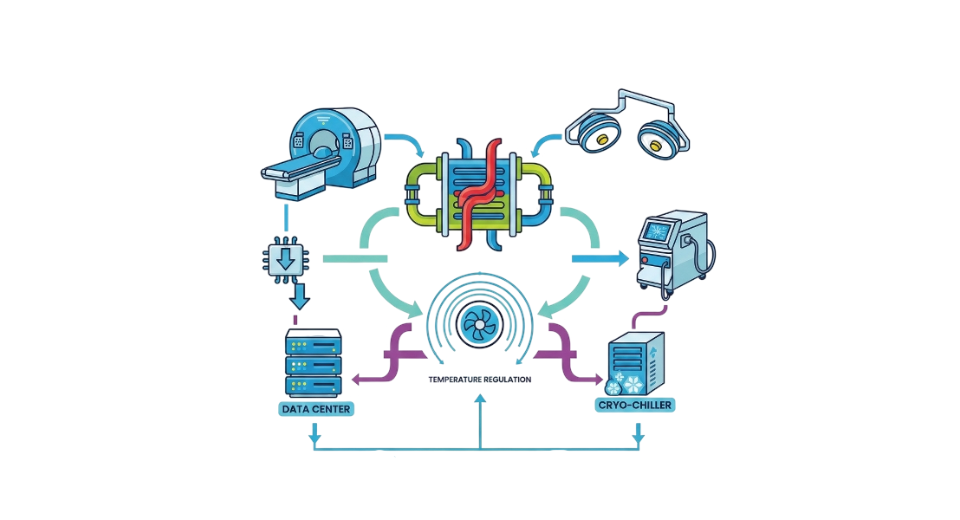

Cooling gear matters because it keeps medical machines running right. When high-tech tools like MRI scanners or laser units work, they produce a lot of heat -so staying cool avoids breakdowns. Machines last longer when the temperature stays under control. Overheating can disrupt hospital workflows, so stable cooling supports smoother operations. Some devices rely on steady temperatures just to turn on at all. Without proper airflow or liquid systems, sensitive parts wear out faster. Even small spikes in heat may affect accuracy during tests or treatments. Keeping things balanced helps avoid surprise shutdowns mid-procedure. In busy clinics, reliable function means fewer interruptions. Temperature shifts behind the scenes influence how well technology performs upfront.

Compact medical tools now need quieter, smaller ways to stay cool. As gadgets shrink yet grow stronger, fresh methods beat older ones. Liquid-based cooling shows up more often inside high-end machines. Instead of loud fans, some gear uses solid-state parts that move heat quietly. Patient ease matters just as much as device precision during design. Heat escapes faster when materials work smarter, not harder. Electronics packed tightly push engineers toward sleek thermal fixes.

It's no secret that safer care and tighter rules are pushing things forward. Because hospitals must follow strict guidelines, steady cooling matters more than ever. When machines run without pause, they depend on systems that hold up under pressure. With clinics updating tools regularly, better ways to manage heat stay in high demand. Growth keeps coming, not from flash but from what simply needs to work.

The Liquid Cooling Systems segment is projected to witness the highest CAGR in the Medical Equipment Cooling market during the forecast period.

According to Transpire Insight, when it comes to handling intense heat from cutting-edge medical gear, liquids tend to outperform air. Because machines like MRI units, CT arrays, and laser treatment tools need steady thermal conditions, fluid-driven methods step in smoothly. Growth forecasts show this approach gaining speed faster than others in the field. Such systems run with less waste, fewer hiccups, and often last longer under pressure. As performance demands climb, many new devices lean into liquid setups naturally. Efficiency becomes obvious when temperatures stay locked without constant adjustments. The shift reflects real needs, not trends or hype, just better function where stability matters most.

Tiny gadgets in medicine now run cooler due to smarter tech shrinking parts. Because machines must stay quiet, small, and frugal with power, companies build fluid-based coolers that slip right into tight medical setups. When gear runs nonstop, keeping patients safe means sticking to tough rules, so clinics and builders alike lean on liquid cooling to meet those demands. This push helps the market climb steadily year after year.

The Imaging Equipment segment is projected to witness the highest CAGR in the Medical Equipment Cooling market during the forecast period.

When imaging gear runs nonstop, it heats fast, so cooling matters more now than ever. Machines like MRIs, CT units, or sharp-detail X-ray tools need steady temperatures just to work right. Growth in medical cooling ties closely to how often hospitals choose high-end scanning tech these days. Without proper thermal control, results could blur, performance might drop, or even risk showing up. Keeping things cool helps images stay clear, devices run smoothly, and people remain safe throughout.

Fresh tech upgrades in scanners, like stronger magnets and quicker picture handling, are pushing the need for better cooling. Because machines run longer when they stay cool, makers now build smarter temperature controls right into the gear. Hospitals keep upgrading their tools for spotting illnesses earlier, which keeps the pressure on cooling systems to perform. With medical centers pouring resources into sharper diagnostics, solid heat control stays a must-have through the coming years.

The Heat Exchangers segment is projected to witness the highest CAGR in the Medical Equipment Cooling market during the forecast period.

According to Transpire Insight, Growth looks likely in the Heat Exchangers part of the Medical Equipment Cooling scene, simply because shifting heat effectively matters so much. Since keeping temperature steady counts, these parts show up everywhere imaging gear, lasers, and lab tools, all relying on them. No problem, as long as temps stay flat and operation stays smooth. Performance holds firm, mainly when thermal control does its job without fuss. That kind of reliability keeps demand ticking higher over time.

Built better with tougher materials and tighter layouts, today’s heat exchangers move cool air more effectively without needing extra space or power. Because machines in healthcare must work nonstop without failure, companies now lean on stronger cooling parts that hold up under pressure. When gear gets smaller but works harder, staying cool matters even more, so sharper thermal solutions keep showing up where precision counts.

The Hospitals & Clinics segment is projected to witness the highest CAGR in the Medical Equipment Cooling market during the forecast period.

Most hospitals and clinics are expected to drive expansion in medical gear cooling through the coming years. Because high-tech scanning tools, life monitors, and treatment machines run constantly, heat builds up fast. When complex imaging units stay active hour after hour, cooling becomes less about comfort - it keeps everything running without fail. Patient care stays steady when vital instruments do not overheat. Surgical setups also depend on stable temperatures behind the scenes. Without proper airflow, delicate electronics can falter mid-procedure. So quiet, consistent cooling runs beneath every checkup and operation.

Fresh funding flowing into health services, along with upgrades to medical centers, pushes clinics to seek better ways to keep machines cool. Because gear must run without stopping, meet tight safety rules, and help deliver stronger patient outcomes, steady cooling becomes essential. Equipment performance stays strong when temperature control works quietly behind the scenes. Providers lean on long-lasting units that handle stress without failing. Growth in this area ties directly to how well technology supports daily operations.

The North America region is projected to witness the highest CAGR in the Medical Equipment Cooling market during the forecast period.

Growth across North America should reshape the Medical Equipment Cooling market, thanks to widespread use of cutting-edge medical tools alongside solid health networks. Outcomes depend heavily on stable cooling - machines like MRIs, CT scanners, and lasers need it to run smoothly, avoid heat damage, plus keep patients out of harm’s way. Because hospitals here pour resources into tech improvements and facility updates, better cooling setups become more essential by the day. Not every region moves at this pace, yet demand keeps building where innovation meets care.

Strict rules plus a clear need for dependable, safe tools push clinics and makers to add advanced cooling systems into devices and daily work. Because spending on health care is high across the United States, alongside steady research efforts and quick uptake of new heat control methods, the region gains an edge. All these pieces together hold up North America’s central spot and ongoing need in the gear-cooling space for medicine.

Key Players

Top companies include Daikin Industries, Glen Dimplex Group, Copeland, Boyd Chillers, American Chillers, Atlas Copco, Drake Refrigeration, Ecochillers, EKS Thermal Systems, ELGi Equipment, Filtrine Manufacturing Company, General Air Products, Haskris, Ingersoll Rand, Johnson Thermal Systems, and Motivair Corporation.

Drop us an email at:

Call us on:

+91 7666513636