Jan 06, 2026

The report “Agriculture Equipment Market By Product Type (Tractors, Harvesting Equipment, Tillage Equipment, Planting & Seedling Equipment, Irrigation Equipment, Others), By Function (Land Development & Seedbed Preparation, Sowing & Planting, Harvesting & Threshing, Irrigation & Crop Care, Post-Harvest Processing), By Automation Level (Manual, Semi-Automatic Equipment and Fully Automatic), By Application (Agriculture, Horticulture, Livestock Farming Forestry)” is expected to reach USD 303.93 billion by 2033, registering a CAGR of 6.70% from 2026 to 2033, according to a new report by Transpire Insight.

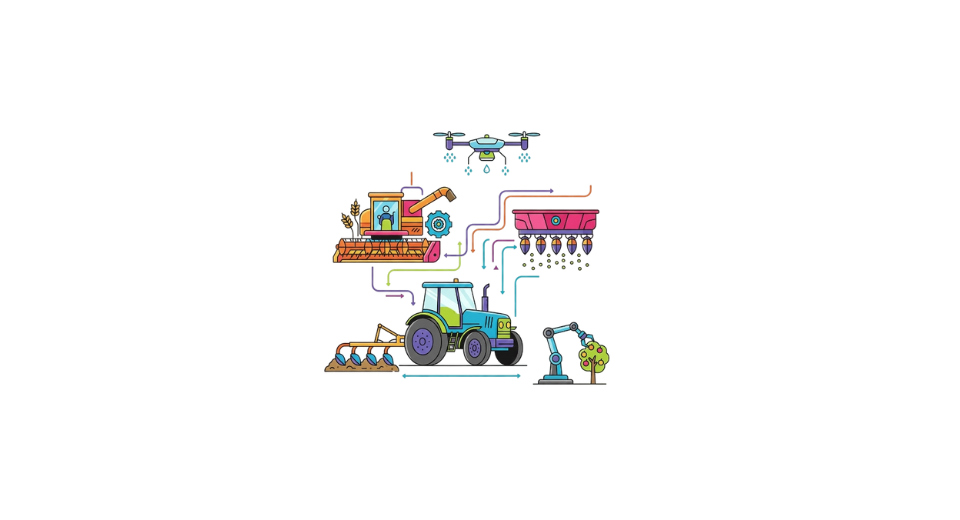

Farming machines help growers get more work done with less effort. From tractors to harvesters, each tool has a specific job on the land. Though small fields differ from large ones, both rely on gear that saves time. Instead of manual digging, planters place seeds evenly into soil rows. Irrigation setups deliver water where it's needed most. While pests threaten crops, sprayers reduce damage early. Tools for plowing reshape the earth before sowing begins. Over time, using these devices leads to steadier food output.

Fresh hunger around the world pushes change, while usable farmland gets smaller each year. Machines now step in where workers once stood, helping grow more with less effort. Efficiency becomes key when every drop and seed counts. Tools guided by data replace guesswork in fields under stress. Digital links turn tractors into smart helpers across uneven terrain. Automation quietly takes root, not because it's flashy, but because it works.

Out on fields far from city lights, new tools quietly reshape how crops grow. Tractors that find their own way across soil now work beside machines running without drivers. Sensors tucked into the earth send updates through invisible networks, helping farmers watch conditions in real time. Some of these machines run on batteries instead of diesel, shifting power sources under open skies. Backed by support from national programs, many growers choose upgrades they could not afford before. Cash aids and policy nudges make it easier to switch from old ways to new ones. Across continents like Asia Pacific and parts of Latin America, fresh interest sparks rapid change. Though progress spreads fast there, North America and Europe still stay ahead, having started earlier with more machinery already in place.

The Tractors segment is projected to witness the highest CAGR in the Agriculture Equipment market during the forecast period.

According to Transpire Insight, ahead of the pack, tractors are expected to grow faster than other equipment types in farming over the coming years. Because they handle jobs like tilling soil, seeding crops, moving loads, and managing harvests, their usefulness fuels this rise. Machinery on wheels forms the core of modern farm work, helping growers get more done with fewer people needed out in fields. Technology plays a part too farms using digital tools find value in advanced features such as self-steering via satellite signals or machines that adjust themselves while working. As these high-tech methods spread, so does the need for updated tractor models.

On top of that, bigger commercial farms are popping up, plus state-backed moves toward machine-driven farming help push tractor numbers higher. Machines now run on electric power or mix fuel types, work without drivers, link into smart networks using data tools - this makes them sharper and kinder to the planet. Food needs keep climbing, workers are harder to find, good land use matters more than ever, so tractors stay ahead as go-to gear for fields, keeping income streams strong across coming years.

The Harvesting & Threshing segment is projected to witness the highest CAGR in the Agriculture Equipment market during the forecast period.

Farmers spend less time bending over fields because machines now handle cutting, separating grain, and then clearing debris. This shift speeds up work while lowering expenses. Equipment that gathers crops plus prepares them afterward grows more popular as farms get bigger and hands-on labor gets harder to find. Instead of relying only on people, many growers choose tools that pull plants from the soil, shake out seeds, then sort what's useful, all without constant supervision. As harvest routines turn more automated, devices meant for collecting and processing yields see greater interest across wide stretches of farmland. Machines step in where manpower slows things down, reducing wasted produce simply by working faster and more steadily than human crews.

Out in fields where work once moved slowly, machines now steer themselves using signals from space. These smart harvesters sort grain on the go, adjusting without human touch. Sensors scattered through equipment send updates in real time, helping farmers track performance quietly. Support comes from above, too - governments hand out help buying new tools, making upgrades easier to afford. With fewer hands willing to do fieldwork, farms turn more often to steel helpers that never tire. Hunger keeps growing around the world, pushing growers to produce faster and cleaner. Machines that pull crops and separate seed by the hour are becoming a common sight. Their rise feeds a broader shift - tractors, headers, and processors fill barns where only hoes used to hang. Growth is not just happening here and there - it spreads wide, reshaping how food leaves soil.

The Fully Automatic segment is projected to witness the highest CAGR in the Agriculture Equipment market during the forecast period.

According to Transpire Insight, A shift toward hands-free machinery on farmland. Machines that steer themselves are gaining ground fast, fueled by a need to do more work with fewer workers. Think driverless tractors gliding through fields, robots picking crops, seed planters adjusting on their own. Less manual control means tighter timing, better consistency, and smoother runs over big plots. Efficiency rises when the gear works smarter, not harder. This corner of farm tech is growing quicker than others right now.

Out in fields far from city lights, machines now move without drivers, guided by signals from above. These smart tools connect through invisible networks, adjusting their work based on real-time data. When workers are hard to find and expenses climb, owners look for ways to do more with less. Watching crops closely from afar helps make quick decisions, cutting down wasted effort. Yield matters most, so any machine that reduces mistakes gains trust over time. Growth seems likely for gear that operates on its own, simply because it fits today’s needs. Innovation isn’t just coming - it’s already rolling across the soil.

The Agriculture segment is projected to witness the highest CAGR in the Agriculture Equipment market during the forecast period.

Fueled by shrinking crews, farms now lean on gear that moves without help. Self-steering rigs spread quickly across the soil and row. Picture tractors rolling solo at dawn, bots grabbing ripe fruit, drills tweaking depth mid-field. When humans step back, operations sync tighter. Timing locks in. Repetition sharpens. Large stretches of land run quieter, steadier, day after day. Machines gain ground by thinking ahead instead of pushing through. Right now, this part of farming tools moves faster than the rest.

High up in the sky, silent signals steer tractors across open land where no one sits behind the wheel. Out there, hidden links tie devices together, shifting tasks as fresh numbers arrive every few seconds. Help grows scarce, costs rise, and this pushes farmers toward solutions that stretch each resource thin. From a distance, eyes track green rows, feeding choices before problems spread too wide. Over seasons, fewer errors mean a stronger belief in a gear that works on its own. Fueled by current demands, standalone machinery appears set to rise. Already moving through fields, progress shows up not as promise but practice.

The North America region is projected to witness the highest CAGR in the Agriculture Equipment market during the forecast period.

Fewer hands-on fields push farmers toward machines that go it alone. Across furrows and flat earth, driverless systems creep forward. Imagine dawn light hitting a tractor moving itself, mechanical arms plucking apples, seed tools adjusting as they roll. As people pull away, tasks link more smoothly. Schedules tighten. Actions grow precise. Vast plots hum with a steady rhythm, unchanged from morning to night. Faster every day, machines choose their next move before acting. This piece of farm gear runs well beyond the others.

Floating above, quiet pulses guide driverless machines through empty fields. Elsewhere, invisible threads connect gadgets, adjusting chores when new data shows up fast. Workers are hard to find, prices climb, forcing growers to stretch every tool further. Far away, watchers study growing lines, making moves before trouble spreads. Year after year, fewer mistakes build trust in equipment that acts alone. Out there in the open, machines working alone are gaining ground fast. Right now, they are not just ideas; they are already at work across the land.

Key Players

Top companies include AGCO Corporation, Deere & Company, CNH Industrial N.V, Kubota Corporation, Mahindra & Mahindra Ltd, Yanmar Co. Ltd, Claas KgaA MbH, Escorts Limited, Agro Tractors SpA, JCB Agriculture, Buhler Industries, Valtra Oy, Great Plains Manufacturing Inc., and Agro Tactors.

Drop us an email at:

Call us on:

+91 7666513636