Market Summary

The global Ultrasonic Sensors market size was valued at USD 6.40 billion in 2025 and is projected to reach USD 15.80 billion by 2033, growing at a CAGR of 11.80% from 2026 to 2033. Heavy use in factory robots gives ultrasonic sensors a boost, while cars that park themselves add more push. Tough places needing precise measurements without touch are now leaning hard on these tools, pulling the business wider. What once stayed behind the scenes now spreads fast through tough spots where only exact readings work.

Market Size & Forecast

- 2025 Market Size: USD 6.40 Billion

- 2033 Projected Market Size: USD 15.80 Billion

- CAGR (2026-2033): 11.80%

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

Key Market Trends Analysis

- The North American market share is estimated to be approximately 40% in 2026. What pushes growth is not just machines working smarter. Safety systems in vehicles play a big role, too. Some industries start using new tools long before others catch on.

- North America holds the biggest slice of the market, driven by heavy vehicle manufacturing alongside efforts toward smarter factories. Investment in sensing tech adds weight here, helping build a lead that sticks. This edge grows where machines learn faster, and tools adapt early.

- On top of a booming factory sector, Asia sees more cars rolling off production lines. Machines in homes and factories now run with smarter sensing tech inside. Growth here outpaces most others thanks to these shifts. More devices mean more demand for tiny electronic eyes and ears everywhere.

- Proximity Sensor share approximately 35% in 2026. Sitting right up front, proximity sensors pull ahead because they spot nearby objects in many automated setups. Cars rely on them just as much as factory gear does when figuring out what's close by.

- These days, more factories choose sensors that work without touching due to fewer breakdowns and less mess over time.

- What stands out is object detection, rising fast thanks to heavy adoption across automated systems. Machines rely on it more now, especially in robots that move and cars built to avoid crashes. Growth comes not just from labs but from real-world needs piling up everywhere.

- Into cars they are moving fast now, with makers adding ultrasonic sensors to help drive and park better. New tools arrive quickly, tied right into how vehicles assist themselves on roads or in tight spots.

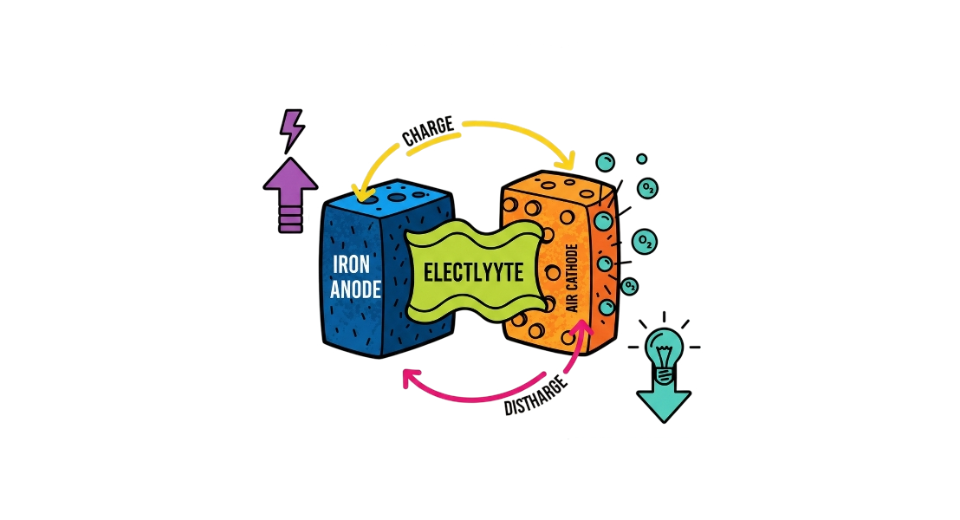

Growth in ultrasonic sensors market is picking up fast, due to more industries wanting contactless detection methods. High-pitched sound waves help these devices sense if something is near, how far it is, or whether it's moving - ideal when accuracy and long life matter. Even in tough spots filled with dirt, water, or uneven light, they keep working where others might fail. Optical systems often struggle under such conditions, which explains why many now lean toward ultrasound instead.

From deep inside factory lines, ultrasonic sensors help spot objects and check fluid levels while guiding how machines respond. As digital plants rise, these tools now fit into nearly every corner where speed and precision matter more than before. Machines that move on their own push need higher sensors that must keep pace without slowing down output.

Few places rely on tech as cars do; ultrasonic sensors pop up in parking helpers, spotting road hazards, and also feeding data to driver aids. Tougher safety rules push makers to pack more sensing gear into today’s models, while buyers wanting smarter protection add pressure too. Electric cars roll in, self-driving ideas grow, and each shift opens fresh space for these small detectors to take hold.

Fresh strides in tech keep lifting how well sensors work, smaller builds, sharper signal handling, and now syncing smoothly with networked devices. Built tiny and sipping power, today’s sensors hit high precision marks, fitting tight spaces inside intelligent gadgets. With factories, farms, and cities pulling more machines online, one thing holds steady: ultrasonic types stay at the core of what watches, listens, and responds across live systems.

Ultrasonic Sensors Segmentation

By Type

- Proximity Sensors

Close-range detectors pop up everywhere machines need to sense nearby items. These gadgets help keep automated setups running smoothly, while also adding a layer of protection. Often found where precision matters most, they quietly track presence without physical contact. Their role spans tasks from halting equipment before accidents happen to guiding robotic arms during assembly.

- Retro-Reflective Sensors

Sound bounces back to these sensors, spotting items nearby without fuss. Distance matters less when echoes do the work quietly.

- Through Beam Sensors

One beam shoots from a sender and lands precisely on its matching receiver. Detection happens when something blocks that path. The distance between parts can stretch far without losing reliability. Precision stays strong even in tough conditions. Separate pieces work together quietly across space.

By Technology

- Contact Type

With a setup built for touching what it measures, this type fits tasks like tracking how high fluid sits inside containers. It works where contact is needed, especially when checking levels of liquids.

- Non-Contact Type

Avoids touch entirely, so measurements stay precise even when conditions get rough. Works well where delicate handling matters most.

By Application

- Level Measurement

Watching how high stuff sits inside containers, liquids or solids, is what level measurement does. It keeps track of volume in storage spots without guessing. Instead of assuming, sensors show real amounts over time. This helps avoid overflow or running empty by mistake. Tanks stay under control because changes appear right away.

- Distance Measurement

Measuring how far apart things are helps machines know where they need to be. With exact figures, movement becomes smoother during automated processes. Positioning improves when distances are calculated correctly every time. Accuracy matters most when systems rely on location data. Instead of guessing, clear numbers guide each step forward.

- Object Detection

Spotting items inside machines or vehicles shows if they are there or missing. Sometimes things show up clearly, other times they vanish without a trace.

- Flow Measurement

Faster flow means more volume passing through these tracks, and how much moves where. Equipment in pipes watches speed using sensors along the route. Movement data helps control what goes into tanks or reactors. Each reading adjusts timing for transfers across stations.

- Anti-Collision Detection

Crash avoidance tech helps machines and cars stay safe by spotting possible bumps ahead. When obstacles show up, this system reacts, so crashes happen less often. Instead of waiting, it acts - keeping things moving without surprise stops. Safety gets a boost when warnings come early, way before contact might occur.

By End-Users

- Automotive

Cars use it for help when backing up, and inside tools that boost driver safety.

- Industrial Manufacturing

Factories rely on it to run machines, move supplies, one step at a time. Systems stay steady because of how tasks link together behind the scenes.

- Healthcare

Few tools help spot illness faster; these work inside machines that check your body. Some gadgets rely on quiet smarts hidden beneath plastic panels. Not all fixes come from drugs; clever hardware chips in, too.

- Food & Beverages

Used for hygienic level and packaging monitoring applications.

- Oil & Gas

Even under tough demands, oil and gas setups rely on steady readings for volume and movement. Harsh environments still need consistent tracking of how much flows through pipes. Systems stay online when conditions push normal limits. Monitoring keeps going where temperature and pressure challenge most tools. Level checks pair with motion sensing even in extreme zones.

- Consumer Electronics

Smart gadgets and automated homes now include these electronics. Devices talk to each other quietly behind walls. Hidden tech responds when spoken to. Some machines learn routines without being told twice. Every day, tools wake up smarter than before.

Regional Insights

Over in North America, ultrasonic sensors have stayed popular because cars, factories, medical tools, and aircraft need accurate detection systems. Thanks to heavy spending on research, quick uptake of smart production tech, plus features such as help when backing up vehicles or checking product quality, the area keeps growing at a reliable pace. In Europe, things look much alike, sensors pop up often in vehicle safety setups, robotic arms, and connected plants. Tough rules around protection and emissions push companies to include more sensors in their designs, which helps keep demand strong across the continent.

Fastest gains now show up across Asia Pacific, driven by surging factory activity and rising vehicle output. Automation spreads quickly through nations like China, India, Japan, and South Korea. Production lines grow busier; appetite for gadgets, intelligent devices climbs higher. More factories mean more need for ultrasonic sensors. This area becomes central not just active for what comes next in market expansion.

Starting in Latin America, along with parts of the Middle East and Africa, they are not leading in size, but they’re inching forward. Growth sneaks in as industries shift toward automation, cities build more infrastructure, and car manufacturing picks up pace. Take Brazil and Mexico, both stand out across Latin nations by adding momentum. Meanwhile, farther east, Gulf states push ahead with smarter urban plans and tech upgrades, quietly pulling the need for ultrasonic sensors into daily operations.

Recent Development News

- January 6, 2026 – ScioSense debuts low-power ultraonic flow sensor for multi-year battery life.

(Source: https://timestech.in/sciosense-debuts-low-power-ultrasonic-flow-sensor-for-multi-year-battery-life/)

- November 17, 2025 – ifm launched new SU Puresonic hygienic ultrasonic sensors.

(Source: https://www.engineerlive.com/content/ifm-launches-new-su-puresonic-hygienic-ultrasonic-sensor)

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 6.40 Billion |

|

Market size value in 2026 |

USD 7.20 Billion |

|

Revenue forecast in 2033 |

USD 15.80 Billion |

|

Growth rate |

CAGR of 11.80% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

Sensata Technologies, Pepperl+Fuchs, Balluff, Siemens, ifm electronic, Banner Engineering, Sick AG, Pepperl+Fuchs GmbH, Keyence Corporation, Turck, Omron Corporation, Panasonic Corporation, Bosch Sensortec, Honeywell International, TE Connectivity, Schneider Electric, and Autonics |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Type (Proximity Sensors, Retro-Reflective Sensors, Through-Beam Sensors), By Technology (Contact Type, Non-Contact Type), By Application (Level Measurement, Distance Measurement, Object Detection, Flow Measurement, Anti-Collision Detection), By End-Users (Automotive, Industrial Manufacturing, Healthcare, Food & Beverages, Oil & Gas, Consumer Electronics) |

Key Ultrasonic Sensors Company Insights

One hundred years ago, the journey began. Now, Sensata builds vital sensors powering machines everywhere. Instead of just making parts, they shape how devices detect change and respond. From cars to factories, their tools help systems run more smoothly and stay safer. Think air conditioners that adapt instantly or planes monitoring critical shifts mid-flight. Even parking gets smarter because ultrasound tech guides vehicles without guesswork. Heavy trucks rely on these components daily, avoiding collisions through precise awareness. Not every sensor does it all, yet each one meets tough demands where failure is not an option. Innovation here means solving real problems quietly, behind the scenes. Engineering complexity fades when results work seamlessly in harsh conditions. Across industries, reliability becomes invisible.

Key Ultrasonic Sensors Companies:

- Sensata Technologies

- Pepperl+Fuchs

- Balluff

- Siemens

- ifm electronic

- Banner Engineering

- Sick AG

- Pepperl+Fuchs GmbH

- Keyence Corporation

- Turck

- Omron Corporation

- Panasonic Corporation

- Bosch Sensortec

- Honeywell International

- TE Connectivity

- Schneider Electric

- Autonics

Global Ultrasonic Sensors Market Report Segmentation

By Type

- Proximity Sensors

- Retro-Reflective Sensors

- Through-Beam Sensors

By Technology

- Contact Type

- Non-Contact Type

By Application

- Level Measurement

- Distance Measurement

- Object Detection

- Flow Measurement

- Anti-Collision Detection

By End-Users

- Automotive

- Industrial Manufacturing

- Healthcare

- Food & Beverages

- Oil & Gas

- Consumer Electronics

Regional Outlook

- North America

- United States

- Canada

- Mexico

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- United Arab Emirates

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636