Market Summary

The global Fab Automation market size was valued at USD 25.24 billion in 2025 and is projected to reach USD 44.48 billion by 2033, growing at a CAGR of 7.34% from 2026 to 2033. Growth in the fab automation market is supported by rising semiconductor complexity, shrinking node sizes, and the need for near-zero defect manufacturing. Increasing capital investment in advanced fabs, particularly for memory and logic chips, is fast-tracking adoption of robots, sensors, and factory control systems. Manufacturers are prioritizing automation to expand yield consistency, decrease human error, and achieve high-volume wafer handling. Additionally, supply chain resilience initiatives and smart factory adoption are reinforcing long-term automation demand.

Market Size & Forecast

- 2025 Market Size: USD 25.24 Billion

- 2033 Projected Market Size: USD 44.48 Billion

- CAGR (2026-2033): 7.34%

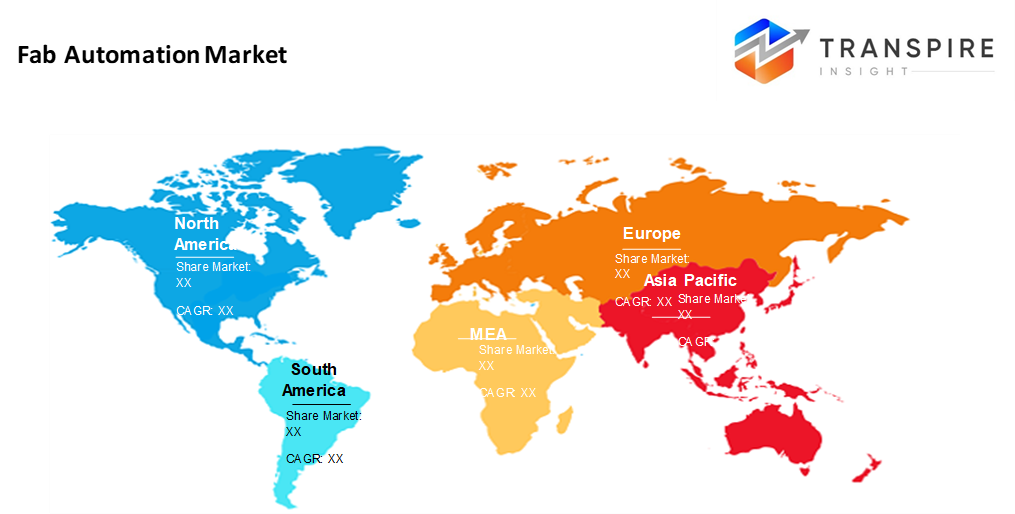

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

To learn more about this report, Download Free Sample Report

Key Market Trends Analysis

- The North America market share is estimated to be approximately 29% in 2026. Right now, North America stays ahead in factory automation. This happens because so many cutting-edge chip research centers are based there. Big names in contract production also help push things forward. Factories started using digital tools much earlier than elsewhere. The mix of innovation and infrastructure keeps progress steady.

- Fueled by heavy spending on local chip manufacturing, the United States holds strong as a major market. Automation pushes forward, tied closely to progress in artificial intelligence. Cloud infrastructure expands alongside next-gen computing needs. Factories adapt rapidly, shaping how circuits are built at scale. Investment flows steadily into high-tech production lines. Demand stays firm, rooted in modern digital demands.

- China leads the charge across the Asia Pacific, where factories grow quickly thanks to rising automation. South Korea follows close behind, driven by strong tech investments. In Taiwan, chip production climbs as facilities modernize. Japan shifts toward smarter manufacturing amid steady upgrades. Memory and foundry work dominate expansion plans. Growth here outpaces other regions overall.

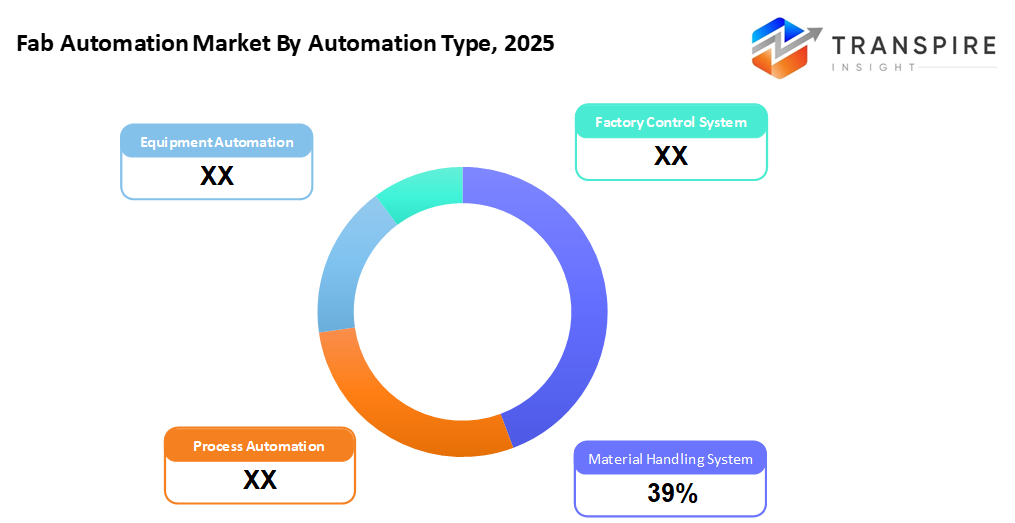

- Material Handling Systems share approximately 42% in 2026. Fab facilities now rely more on automation when moving and storing wafers. This shift cuts down impurities while speeding up output. Running plants without constant human presence becomes easier this way. Machines handling materials help achieve that goal quietly, steadily.

- Software takes the lead when smarter systems like modern MES, live data forecasting, and instant adjustments boost output, keep machines running longer, while tightening control over production steps.

- Fab Type Foundries leads here, contract makers speed up automation to manage wide-ranging client workflows alongside heavy output demands.

- Fabrication at advanced nodes leans heavily on automated steps, lithography, etch, and deposition, where tiny errors matter most. Precision climbs when machines handle wafers instead of humans. Repeatability locks in consistency across thousands of units. Yield improves not by luck but through controlled environments and tight feedback loops. This part of production takes up the biggest share simply because modern chips demand near-perfect execution every single time.

Nowhere else are machines taking over like they are doing inside chip plants, speeding things up, cutting errors, and leaving less to chance. Material movers glide between stations, software tunes each step of production, tools run on their own, while central brains track it all through MES networks. Not just one thing pushes this shift; it is AI needing faster chips, cars packing more sensors, phones demanding better performance, plus 5G spreading fast. Each new device pulls the whole system forward, quietly reshaping how silicon gets made.

Fab automation grows because precision matters. Clean handling of wafers becomes non-negotiable when even tiny flaws ruin chips. Speed picks up when machines take over the movement between steps. Quality stays steady across runs, not left to chance. Instead of hands, robotic arms carry delicate materials through tight spaces. Sensors watch conditions minute by minute, feeding data where it's needed. Controllers adjust tools on the fly using feedback from live measurements. Software ties everything together: timing, placement, response. Chipmakers face tighter designs across many technology nodes. Mistakes drop sharply once manual steps fade out. Factories building processors, discrete devices, or memory stacks choose automated paths more often now.

Fab operations now lean heavily on smart software, peeking ahead at machine wear, plus live tracking of production flow. New moves in the game show up as artificial intelligence shaping how steps unfold, robots that shift easily between wafer types, and tighter links forming between shop floor controls and factory-wide management tools.

Down the road, new tech steps forward while teams across industries link up more closely. Equipment makers join forces with software developers and chip builders, and government backing adds fuel to the fire, too. Instead of slowing down, rising costs and tough engineering hurdles face steady demand head-on. Precision at scale keeps pulling the factory floor into tomorrow, one automated move after another.

Fab Automation Market Segmentation

By Automation Type

- Material Handling Systems

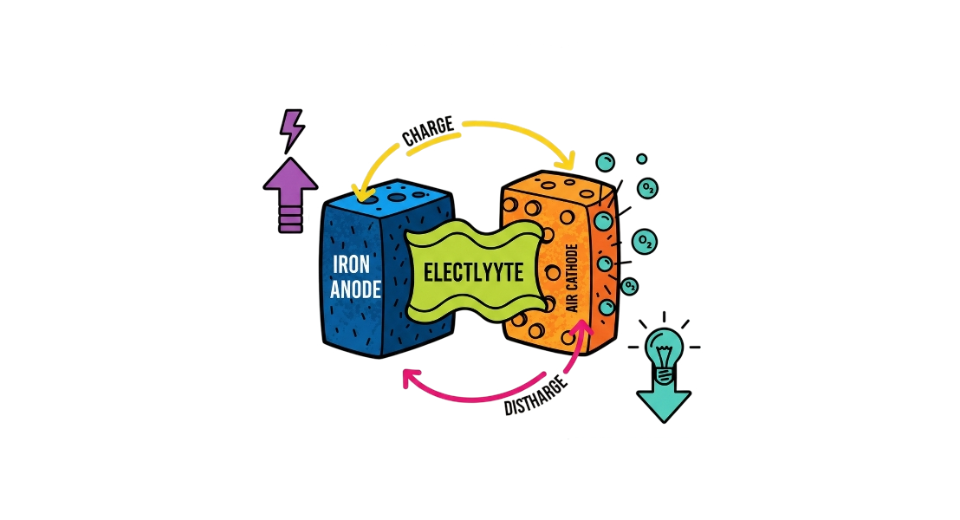

Fresh air flows better when machines move wafers without human hands touching them. Storage gets smarter as robots handle placement, avoiding dust buildup along the way. Retrieval speeds up because paths are planned ahead of time. Efficiency climbs since delays shrink during transfers between stations.

- Process Automation

Starting with precision, it manages key steps like patterning silicon wafers through light exposure. Moving ahead, one task is to adjust how layers are built by shaping surfaces carefully. Control stays tight throughout each phase, ensuring consistency across production runs.

- Equipment Automation

Instead of random adjustments, changes follow set patterns that improve outcomes over time.

Running machines on their own, this setup handles tasks, checks performance, and watches outputs. Control happens without constant human input, streamlines production steps, and keeps processes steady. Tools respond to preset rules, adjust actions based on feedback, and maintain precision throughout fabrication.

- Factory Control Systems

From the shop floor up, it ties together production planning with real-time oversight and system-driven operations across the entire facility.

To learn more about this report, Download Free Sample Report

By Component

- Robots

Inside sterile rooms, machines move silicon wafers without error. Their touch stays pure, never introducing impurities. Precision guides every motion they make. Clean spaces rely on their steady operation.

- Sensors

From time to time, sensors keep an eye on how things are running inside a system. They track shifts in temperature, pressure, or flow that might affect results. When something changes, they help adjust before problems grow. Their job is quiet but constant, making sure output stays steady and meets standards.

- Controllers

Machines that run tasks on their own get guided by controllers throughout the facility. These systems keep processes moving without constant human input. The operation flow stays steady thanks to the coordination from these units. Each step in production links smoothly because of how they function behind the scenes.

- Software

- Real-time data analysis comes alive through software tools that also anticipate equipment needs before failure occurs. Machines keep running efficiently because smart systems adjust output based on live feedback. Predictions guide upkeep schedules instead of waiting for breakdowns. Optimization happens continuously, driven by what the system learns over time.

By Fab Type

- Foundries

Factories making chips rely on smart machines to handle big batches of wafers for many clients at once.

- Integrated Device Manufacturers (IDMs)

Deploy fab automation to improve efficiency in in-house chip manufacturing.

- Memory Fabs

Fab facilities storing memory lean on automated systems to boost output during production of DRAM plus NAND chips. Machines handle delicate steps, so more units work once made.

By Application

- Wafer Processing

Starting with silicon wafers, machines handle each step to reduce human error. These tools move materials through stages without pauses. Precision improves when timing stays exact every time. Consistency comes from repeating actions under steady conditions. Fewer mistakes happen once systems run on their own.

- Wafer Transport & Storage

Inside the factory, wafers move quickly without damage thanks to smart handling systems. Their storage stays secure while keeping pace with production demands.

- Inspection & Metrology

A fresh look at inspection and metrology shows machines spotting flaws on their own. These tools measure tiny details without help from people. What happens next is better results in production. Accuracy grows when measurements stay consistent. Yield gets a boost not by luck but through steady checks.

- Assembly & Packaging

Putting chips into packages happens fast here; machines handle it. Testing each unit follows right after, done by automated systems.

Regional Insights

Home to cutting-edge chip makers, vast data centers, and tech-driven design firms, North America shapes the future of factory automation. Leading the charge, the United States pours resources into new fabrication plants, smart control platforms, plus robotic transport solutions. Meanwhile, Canada quietly builds momentum through lab work and component packaging efforts. Pioneering high-precision robotics early on gave the region an edge; its inventive spirit still fuels progress today.

Down south in Asia Pacific, growth surges ahead faster than anywhere else when it comes to factory automation in chipmaking, driven hard by booming output across China, Taiwan, South Korea, and Japan. Moving into India and parts of Southeast Asia, smaller hubs now pour cash into automated foundries, memory factories, and packaging sites. Strong networks for moving goods flow smoothly here, backed heavily by national policies pushing homegrown chip efforts. Demand never slows down either, feeding constant upgrades where making memory and logic chips at scale stays front and center.

Across Europe, countries like Germany, the Netherlands, and France lead in automating chip production, vehicles, and factories. These areas act as core hubs for high-tech fabrication setups. Meanwhile, Italy, Spain, and Nordic nations follow closely, slowly bringing in workflow controls and digital tracking tools. Outside Europe, Latin America and regions across the Middle East, plus Africa, show rising interest in similar technologies. Growth there links to new labs exploring chips, online data platforms, and modern plant upgrades. Though slower to start, these places now build foundational systems for automated manufacturing.

To learn more about this report, Download Free Sample Report

Recent Development News

- December 17, 2025 – Siemens and GlobalFoundries target AI-Driven fab automation and predictive maintenance.

- December 11, 2025 – Mitsubishi Electric inaugurates a new manufacturing plant worth 2,200 MINR for cutting-edge factory automation systems in Maharashtra, India.

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 25.24 Billion |

|

Market size value in 2026 |

USD 27.09 Billion |

|

Revenue forecast in 2033 |

USD 44.48 Billion |

|

Growth rate |

CAGR of 7.34% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

Applied Material Inc., Samsung, Einnosys, Fabmatics, TSMC, Mitsubishi Electric, NXP, Fabrication Automation, Electrotek, Tokyo Electron Limited, Lam Research Corporation, Daifuku Co. Ltd, Atlas Copco, Ebara Corporation, Murata Machinery Ltd, Kuka AG, and KLA Corporation |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Automation Type (Material Handling Systems, Process Automation, Equipment Automation, Factory Control, System) By Component(Robots, Sensors, Controllers, Software’s) By Fab Type (Foundries, Integrated Device Manufacturers, Memory Fabs) By Application (Wafer Processing, Wafer Transport & Storage, Inspection & Metrology, Assembly & Packaging) |

Key Fab Automation Company Insights

A name seen across high-tech labs worldwide, Applied Materials builds machines that move wafers without human touch. Instead of manual steps, robotic arms glide through cleanrooms guided by smart software. These systems keep chips defect-free while speeding up production lines. From Japan to Texas, factories rely on their gear to run smoothly every hour. Think less guesswork, more consistency during critical phases. Software updates flow seamlessly into hardware already online. Collaboration happens daily with top chipmakers designing next-gen processors. Not just tools but full setups come together under one roof. Innovation does not pause here - engineers tweak designs based on real plant data. Trust grows because results show fewer errors month after month.

Key Fab Automation Companies:

- Applied Material Inc.

- Samsung

- Einnosys

- Fabmatics

- TSMC

- Mitsubishi Electric

- NXP

- Fabrication Automation

- Electrotek

- Tokyo Electron Limited

- Lam Research Corporation

- Daifuku Co. Ltd

- Atlas Copco

- Ebara Corporation

- Murata Machinery Ltd

- Kuka AG

- KLA Corporation

Global Fab Automation Market Report Segmentation

By Automation Type

- Material Handling Systems

- Process Automation

- Equipment Automation

- Factory Control Systems

By Component

- Robots

- Sensors

- Controllers

By Fab Type

- Foundries

- Integrated Device Manufacturers

- Memory Fabs

By Application

- Wafer Processing

- Wafer Transport & Storage

- Inspection & Metrology

- Assembly & Packaging

Regional Outlook

- North America

- United States

- Canada

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636