Market Summary

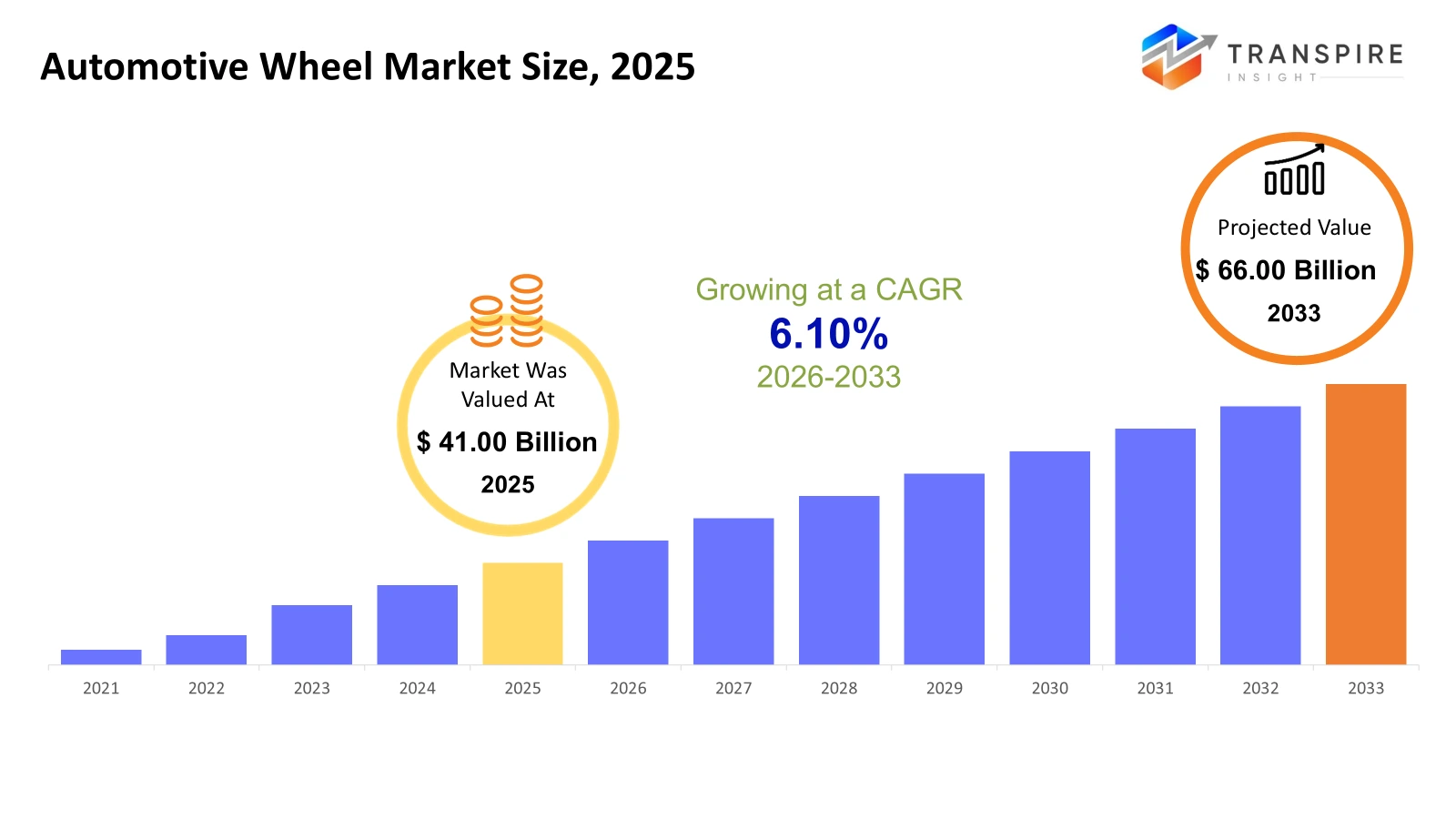

The global Automotive Wheel market size was valued at USD 41.00 billion in 2025 and is projected to reach USD 66.00 billion by 2033, growing at a CAGR of 6.10% from 2026 to 2033. More cars being made around the world push up sales of automotive wheels. Fuel savings and better handling draw buyers toward lighter, stronger designs. Instead of basic models, people now pick stylish custom alloy versions more often. Electric car popularity rises fast, which pulls in new types of light but tough wheel materials. Production climbs keep factories busy meeting fresh needs across regions.

Market Size & Forecast

- 2025 Market Size: USD 41.00 Billion

- 2033 Projected Market Size: USD 66.00 Billion

- CAGR (2026-2033): 6.10%

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

To learn more about this report, Download Free Sample Report

Key Market Trends Analysis

- The North American market share is estimated to be approximately 25% in 2026. A sudden shift appears across North America where drivers lean into upgrading their ride. Custom wheels matter more now than before. Aftermarket energy runs deep here, fed by steady interest in sleek alloys that stand out on highways and backroads alike. Spending flows freely when it comes to personal touches, especially ones boosting how a car looks or handles. Performance tweaks pair naturally with fresh rims, forming habits shaped by choice rather than need.

- Out on American roads, big trucks roll by just as often as family SUVs that cater to larger rides keep demand high for standout rims. Folks swap out factory wheels more than ever, chasing looks as much as tech upgrades. Aftermarket choices thrive because garage customizers want bold finishes and modern designs. Driveways fill up with lifted models spinning flashy alloys. What you see most is a market where size matters, and stock hubs rarely stay put.

- Out there in the Asia Pacific region, wheels are rolling off assembly lines faster than ever. Automotive output keeps climbing, thanks mainly to booming factories across China and India. More people own vehicles now, pushing numbers upward steadily. Aftermarket support is stretching wider, too, adapting to increased needs on the ground. This part of the world pulls ahead globally when it comes to needing more tires

- Alloy Wheel share approximately 60% in 2026. Starting light, alloy wheels dominate new vehicle designs because they cut weight without sacrificing strength. Their rise comes alongside better fuel efficiency, pushing manufacturers to favor them. Not just at factories, drivers often pick these wheels when upgrading later. Growth stays steady worldwide, fed by both production lines and replacement markets. Performance perks keep demand high across regions.

- Most cars on the road are passenger vehicles, so they are still shaping what kinds of wheels sell best. Style matters more now, with buyers picking bold designs even for regular daily drivers. High-end models push it further, leaning into rims that highlight speed and look. Choice isn’t just about function anymore; appearance plays a big role across all levels. Demand holds strong because upgrades feel accessible, yet special.

- That size sits right in the middle where most cars land - good enough on looks, decent on handling, without asking too much money. Though bigger options exist, these wheels stick around because they just work.

- Now growing fast, the aftermarket channel sees more buyers choosing replacement wheels, often picking alloys or personalized styles. People want change plus better looks without waiting for new vehicles. Custom finishes grab attention just as much as durability claims do. Shoppers explore choices outside factory setups, leaning toward unique designs that stand out slightly. Demand shifts slowly but surely away from standard models. Wheel upgrades become common even among budget-focused drivers. Replacement cycles shorten because of social trends rather than mechanical need. Interest spreads through word-of-mouth moments, not ads. More garages start offering fitment services to meet rising requests. Choices multiply at local shops, making access easier over time.

Heavy metal spinning fast beneath every car shifts shape quietly now, reflecting steady innovation in the automotive wheel market. Strength remains essential, but appearance also plays a major role as vehicles move along city streets and highways each day. Weight distribution improves through advanced designs engineered for durability and balance. Smoother rides and better fuel efficiency follow when modern materials and precision manufacturing redefine what supports the tires. Drivers increasingly notice enhanced comfort and performance as lightweight alloys and improved construction methods replace traditional builds. What moves vehicles forward may seem simple, yet continuous evolution in wheel technology shapes both safety and style in ways often overlooked.

More demand for light materials like aluminum alloys and carbon fiber. Cutting down a vehicle's weight comes through these advanced substances. Better gas mileage shows up when things get lighter. Fewer fumes released into the air are linked directly to that reduced mass. Performance gets a nudge upward, yet comfort stays part of the deal. Stopping power sharpens when wheels weigh less. How a car turns and grips the road improves alongside. Drivers notice it whether cruising city blocks or pushing limits on curves. Passenger models gain just as much as high-speed versions do. The pull toward slimmed-down parts keeps building, quietly changing what goes under the hood.

Heavy demand shows up when drivers pick unique rims just to make cars look sharper. These days, more people want that clean alloy finish because it fights rust while lasting longer under tough conditions. Surprisingly light yet strong models arrive through new methods like forging or shaping metal with intense heat and pressure.

Now wheels are getting tougher, thinner, yet kinder to nature - thanks to fresh lab work by makers. Electric cars push changes, too, since how they carry weight matters more now. Smooth shapes that cut air drag show up more often under new models. Buyers want flash, yes, but also muscle, so progress keeps rolling. It sticks around because wishes shift faster than tires spin.

Automotive Wheel Market Segmentation

By Material Type

- Steel Wheels

Built tough but priced low, steel wheels show up often on basic models and work trucks. Though heavy, they handle rough use without failing - common where budget matters most. Toughness wins here instead of flashy looks.

- Alloy Wheels

Faster handling comes from alloy wheels, their light build cutting down weight on the road. Rust stands little chance against these materials, built to hold up over time. Looks matter, too; clean lines give cars a sharper presence. Performance gains pair with visual upgrades, each feeding into the other naturally.

- Carbon Fiber Wheels

Fine threads of carbon, woven tight, form these rims, built light but tough enough for fast machines. Not your everyday set; they show up on sleek cars meant to race or impress. Strength hides in their slim profile, fighting stress without adding bulk. Speed lovers pick them because less weight spinning means quicker moves. Fancy rides roll more easily when burdened less by heavy parts.

To learn more about this report, Download Free Sample Report

By Vehicle Type

- Passenger Vehicles

Most cars on the road drive up need because factories make so many of them. Custom touches keep buyers choosing new models instead of old ones.

- Commercial Vehicles

Heavy trucks need strong wheels built to carry big loads. Tough jobs demand durable parts that will not give way under pressure. These vehicles move weight day after day, so their wheels must last. Strength matters most when the work never slows down.

- Electric Vehicles

Lighter wheels help electric cars go farther on a single charge. Because air resistance slows vehicles, smooth shapes cut through the wind better. Efficiency climbs when parts weigh less. Some designs borrow ideas from racing technology. Shape matters just as much as weight. Wheels built with airflow in mind support longer trips. Reducing drag plays a quiet but vital role.

By Rim Size

- Up to 15 Inches

Fifteen inches tops this size fits small cars that save on fuel. Though bigger tires exist, these stay popular where space is tight.

- 16-18 Inches

Often seen on average-sized cars and taller vehicles, where looks meet function. A middle ground that just fits.

- Above 18 Inches

Bigger than 18 inches tends to show up where looks matter most - think high-end rides, muscle machines, or boxy off-road beasts. Style gets sharper. The way they grip and turn feels tighter, too.

By Sales Channel

- OEM

Manufactured parts go straight to car builders for setup during initial production runs. These rims are installed before the vehicle leaves the plant.

- Aftermarket

Wheels made later by different makers show up in shops, stores far from factories, and also on websites. Some fit right back onto cars already built, others reshape how a vehicle looks entirely.

Regional Insights

Heavy factories keep humming across North America, pushing wheels into new cars at a steady clip. Lighter alloys, flashier rims, and style matter more than before. Rules about gas mileage tighten each year, nudging makers toward smarter, lighter rolling gear. Custom rides sell themselves, so shops respond with bolder finishes and tighter builds. New models roll out faster, feeding a cycle where looks meet efficiency on every street corner.

Heavy rules on pollution and road safety push change across Europe, nudging makers toward lighter, tougher wheels that help cars burn less fuel while cutting exhaust fumes. Car factories rooted deep in Germany, France, and the United Kingdom keep buying advanced alloy and forged versions, whether building new models or supplying replacements later. These regions stay central to what moves the market, shaped more by engineering needs than trends.

Faster than anywhere else, the Asia-Pacific area looks set to grow quickly - driven by more cars being made across China, India, and parts of Southeast Asia. Because people earn more now, they pay closer attention to how their vehicles look, which lifts interest in upgraded wheels. Not just that, but cities spreading fast add even greater push toward personalized choices. On top of it all comes the rise of electric cars, there, quietly helping newer, lighter wheel designs take hold.

To learn more about this report, Download Free Sample Report

Recent Development News

- September 12, 2023 – Uno Minda announced new premium range alloy wheels.

(Source: https://www.autocarpro.in/news/uno-minda-announces-new-premium-range-alloy-wheels-116711)

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 41.00 Billion |

|

Market size value in 2026 |

USD 43.50 Billion |

|

Revenue forecast in 2033 |

USD 66.00 Billion |

|

Growth rate |

CAGR of 6.10% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

Iochpe-Maxion, CITIC Dicastal, Ronal Group, Maxion Wheels, Borbet GmbH, Enkei Corporation, Superior Industries International Inc., Alcoa Wheels (Howmet Aerospace Inc.), Accuride Corporation, Topy Industries Ltd., Zhejiang Wanfeng Auto Wheel Co., Ltd., YHI International Limited, Mangels Industrial S.A., OZ S.p.A., Advanti Racing, Fuel Off-Road Wheels, and American Racing Equipment Inc |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Material Type (Steel Wheels, Alloy Wheels, Carbon Fiber Wheels), By Vehicle Type (Passenger Vehicles, Commercial Vehicles, Electric vehicles), By Rim Size (Up to 15 Inches, 16-18 Inches, Above 18 Inches), By Sales Channel (OEM, Aftermarket) |

Key Automotive Wheel Company Insights

From Brazil, Iochpe-Maxion builds car wheels and parts found around the world, running plants in the Americas, Europe, and Asia. Steel and aluminum rims go out to big carmakers, along with replacement suppliers; quality control stays tight, and output remains large. New designs come together through constant testing, aiming at lighter yet tougher wheels that fit modern driving needs. Working closely with vehicle brands across continents helps hold its place firmly within the industry’s supply chain.

Key Automotive Wheel Companies:

- Iochpe-Maxion

- CITIC Dicastal

- Ronal Group

- Maxion Wheels

- Borbet GmbH

- Enkei Corporation

- Superior Industries International Inc.

- Alcoa Wheels (Howmet Aerospace Inc.)

- Accuride Corporation

- Topy Industries Ltd.

- Zhejiang Wanfeng Auto Wheel Co., Ltd.

- YHI International Limited

- Mangels Industrial S.A.

- OZ S.p.A., Advanti Racing

- Fuel Off-Road Wheels

- American Racing Equipment Inc

Global Automotive Wheel Market Report Segmentation

By Material Type

- Steel Wheels

- Alloy Wheel

- Carbon Fiber Wheels

By Vehicle Type

- Passenger Vehicles

- Commercial Vehicles

- Electric vehicles

By Rim Size

- Up to 15 Inches

- 16-18 Inches

- Above 18 Inches

By Sales Channel

- OEM

- Aftermarket

Regional Outlook

- North America

- United States

- Canada

- Mexico

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- United Arab Emirates

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636