Jan 27, 2026

The report “Steel Wire Rope Market By Material Type (Carbon Steel, Galvanized Steel, Stainless Steel, Others), By Core Type (Independent Wire Rope Core (IWRC), Fiber Core (FC), Wire Strand Core (WSC)), By Coating (Non-plastic coated, Plastic-Coated (PVC/PE/Nylon)) and By End User (Construction & Infrastructure, Industrial & Crane Operations, Mining, Oil & Gas / Energy, Marine & Fishing, Others)” is expected to reach USD 12.85 billion by 2033, registering a CAGR of 7.40% from 2026 to 2033, according to a new report by Transpire Insight.

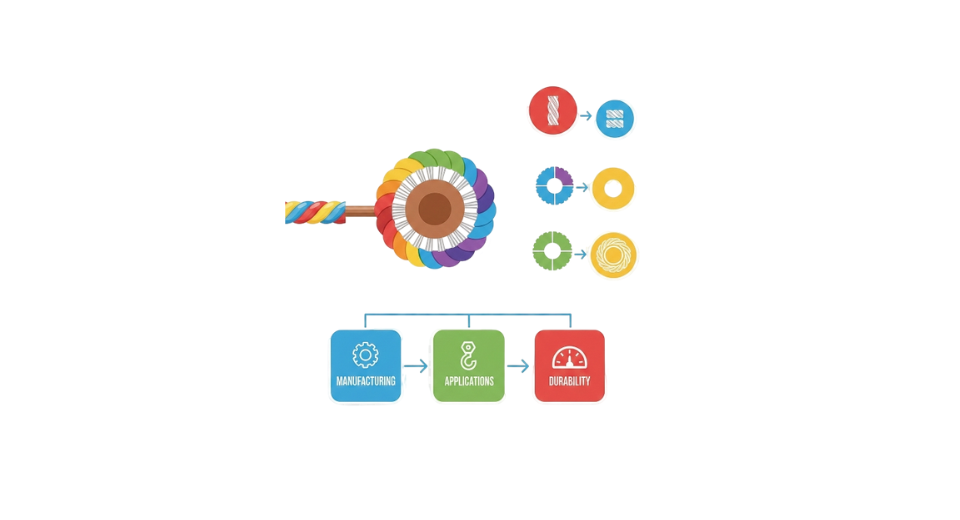

The steel wire rope market signifies a crucial sector in the world’s ecological systems with reference to various sectors that rely on its support for tasks such as lifting, hoisting, towing, and bearing loads in constructions, mining activities, energy sector operations, and marine activities. The steel wire ropes are manufactured with steel wire material with high tensile strength twisted in cores and strands, providing adequate support in all these sectors with reference to flexibility and strength required in heavy-duty activities. The steel wire rope market finds growth in direct proportion with capital investments in infrastructure development activities across the world. The demand trend of steel wire ropes also appears to be gaining momentum owing to factors such as city expansion, expansion in transportation network infrastructure, and replacement of old lifting equipment. Currently, construction and infrastructure development activities hold the maximum market share, followed by mining and energy segment requirements. Continued progress in intermaterial upgrading, including advances in galvanization, helps in marking safe operating trends in terms of enhanced fatigue life and efficiency.

Moreover, there is increasing emphasis being placed by governments in the developed world with regards to workplace safety, which in turn is having a profound effect upon purchasing decisions. For example, there is an increasing emphasis being placed by end users upon quality certification, as opposed to lower-cost alternatives. Although there is volatility in raw material prices, diversified end market demand is expected to help this market grow in the future.

The Galvanized Steel segment is projected to witness the highest CAGR in the Steel Wire Rope during the forecast period.

According to Transpire Insight, Galvanized steel wire ropes can then be said to remain on top as they provide a strong balance of both cost-effectiveness and durability. Given its galvanized coating, steel wire ropes can provide adequate protection against environmental degradation challenges. In other words, steel wire ropes can provide better durability to ensure long service lives for structures adjacent to marine environments. From this value, one can see that galvanized steel wire ropes can provide longevity for desired structures.

From the demand side, the product is dominant due to the extensive usage of galvanized steel wire ropes among construction sites, lifting gear for industrial setups, ports, and different operating activities. The product can withstand moderate exposure levels of moisture and chemical environment without being priced higher than their counterpart, stainless steel wire ropes. Increasing investment in infrastructure and demand for replacement of old wire ropes in mature nations are favoring galvanized steel usage for meeting end user demand, thus ensuring its position as a leader.

The Independent Wire Rope Core (IWRC) segment is projected to witness the highest CAGR in the Steel Wire Rope during the forecast period.

Independent Wire Rope Core (IWRC) signifies one of the most popular core configurations in terms of market segments of Steel Wire Ropes, owing to its outstanding load rating capacity, stability, and ability to avoid deforming. IWRC configurations feature an individual wire rope as part of the core, providing capacity in terms of strength retentions, crushing, and multi-layer spooling and high-temperature exposure. All of these factors identify IWRC configurations as one of the most popular segments of Steel Wire Ropes, in terms of heavy-duty applications including cranes, mining hoists, oil rigs, etc.

From a Market Demand perspective, the dominance of IWRC is further validated by current trends toward improved safety requirements and increased utilization of lifting equipment. End-users' demands for performance consistency, equipment longevity, and increased equipment run time are all met by IWRC configurations. Increases in project scale for infrastructural work, combined with an increase in lifting provisions, particularly for construction and mining industries, see IWRC wire ropes maintain their leading preference, both in terms of volume sales and revenue.

The Non-plastic coated segment is projected to witness the highest CAGR in the Steel Wire Rope during the forecast period.

According to Transpire Insight, Non-plastic coated galvanized steel wire ropes prove to hold the largest market size for coating segment usage, caused by its remarkable balance between corrosion protection, mechanical performance, and cost-effectiveness. The galvanized coating will provide protection to its substrate material against corrosion caused by oxidation and environmental exposures, which can minimize its lifespan when subjected to outdoor applications. This makes galvanized wire ropes useful for construction, material handling, mining, construction lifts, or any type of industrial lifts where long life is desired but not normally warranted for high-tech plastic coatings to begin with.

Based on demand-side factors, galvanized wire ropes enjoy premium advantages in terms of acceptability, specifications, and supply chain pull in developed as well as developing nations. The overall end user preference lies in plastic-coated wire ropes due to their low-cost advantages compared to other wire ropes, but with less performance advantages. Even plastic-coated wire ropes, in some specific applications, give preference to their usage in safety and abrasive materials, thereby cementing their overall position in steel wire ropes.

The Construction & Infrastructure segment is projected to witness the highest CAGR in the Steel Wire Rope during the forecast period.

The segment of construction and infrastructure is the largest of all in steel wire ropes, helped by continuous investments in infrastructure, urban development, transportation infrastructure, and large-scale civil engineering projects undertaken across various regions of the world. Steel wire ropes feature significantly in cranes, hoists, elevators, suspenders, suspended equipment, and material handling equipment, thereby featuring prominently throughout the entire construction spectrum. The continuous growth of residential, commercial, and infrastructure development, especially across the emerging world, is keeping demand steady across infrastructure development.

Therefore, as far as the impact of market dynamics is concerned, the renovation as well as modernization of the infrastructure in the developed regions not only leads to strong leadership in the segment but also points towards the overall replacement requirements. Moreover, it has also led to an increase in the use of wire ropes with higher tensile strength as well as galvanized wire ropes. Therefore, as far as the overall scenario in the steel wire ropes market is concerned, the construction/infrastructure segment appears to have the least amount of volatility.

The North America region is projected to witness the highest CAGR in the Steel Wire Rope during the forecast period.

The region of North America is an established but highly important steel wire rope industry segment, registering consistent demand that comes in the form of product replacement and sustained infrastructure development efforts. The country that is majorly consuming steel wire rope equipment within the region is the USA. This is owing to various infrastructure development efforts that it is undertaking, such as port infrastructure, transportation networks, energy-based infrastructure, and commercial infrastructure. The country of Canada is contributing towards the region by registering consistent mining and energy-based activity, whereas Mexico is doing so by registering extensive manufacturing activity that is taking place within its borders.

Qualitatively, the demand from North America is increasingly influenced by the structure of safety regulations and quality standards and lifecycle cost rather than by the count of volumes alone. The end users show a strong preference for galvanized and high-strength wire ropes with predictable fatigue life and compliance certifications. This shift toward premium and specification-driven products supports the growth in value despite the volume growth being relatively modest. Equally, the automation of warehousing and industrial operations strengthens demand for reliable wire rope systems, placing North America as a high-value, technology-led market.

Key Players

The top 15 players in the Steel Wire Rope market include Kiswire Ltd, Bridon-Bekaert The Ropes Group, WireCo World Group Inc, Usha Martin Limited, Teufelberger Holding AG, Tokyo Rope Mfg Co Ltd, Jiangsu Langshan Wire Rope Co Ltd, PFEIFER Drahtseilwerk GmbH, Guizhou Steel Rope Group, DSR Wire Corporation, Brugg Lifting AG, Juli Sling Co Ltd, Gustav Wolf GmbH, Fasten Group, and Kobelco Wire Co Ltd.

Drop us an email at:

Call us on:

+91 7666513636