Jan 27, 2026

The report “Automated Guided Vehicle Market By Vehicle Type (Tow Vehicles , Unit Load Carriers, Pallet Trucks, Forklift AGVs, Assembly Line Vehicles , Special/Hybrid Types, Others), By Navigation Technology (Laser Guidance , Magnetic Guidance, Vision Guidance, Inductive Guidance, Other Guidance), By Application (Transportation & Distribution, Storage & Assembly, Packaging, Trailer Loading/Unloading, Raw Material Handling, Waste Management) and By End User (Automotive, Manufacturing, Logistics & Warehousing, E?commerce & Retail, Food & Beverage, Healthcare & Others)” is expected to reach USD 25.4 billion by 2033, registering a CAGR of 19.70% from 2026 to 2033, according to a new report by Transpire Insight.

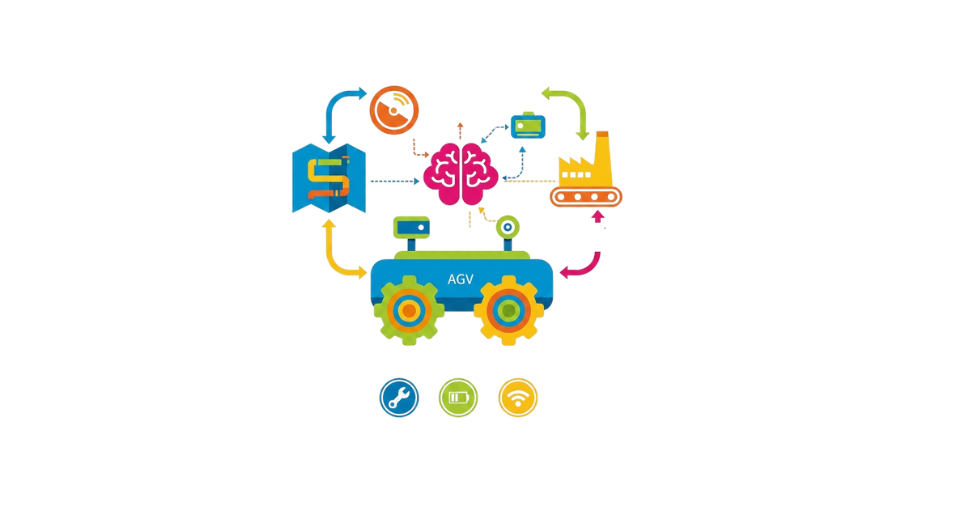

The Automated Guided Vehicle industry has been continuously transforming in recent times, with many industries recognizing the value of automated systems in promoting optimal efficiency, safety, and cost management. AGVs have become an essential feature of modern industrial settings, allowing firms to digitize the material handling process through automated movement systems in their respective industries. The continuous functionality of AGVs allows them to play an essential role in promoting digitization in industries. Demand for AGVs also derives its validation from the challenges identified in the labor market characterized by labor shortages, increased labor costs, and the need to increase the levels of throughput in the chain of supply. Today, industries are slowly transitioning from labor-based material handling to more technology-based material handling for increased accuracy and reproducibility. In addition to this, the rise of e-commerce has also increased the use of AGVs.

Another important factor in the technological evolution of the industry is the changing technological environment; for example, with developments in artificial intelligence systems, machine vision systems, LiDAR systems, as well as advanced software in fleet management systems, the quality of navigation as well as flexibility in navigation systems has improved substantially. This trend in navigation systems allows for the application of navigation systems in various industries or fields other than manufacturing. Looking forward, the market scope appears to be favorable with organizations adopting scalable and modular automation frameworks. There is also a general upsurge in the support being offered to the development of the Smart Factory initiative and the upgradation of the logistics infrastructure. AGV technology will continue to expand its potential for increasing productivity and mitigating operational risk.

The Forklift AGVs segment is projected to witness the highest CAGR in the Automated Guided Vehicle during the forecast period.

According to Transpire Insight, Forklift AGVs are the leading type of vehicles in the Automated Guided Vehicle market owing to their versatility and ability to navigate both horizontal and vertical movements of materials using automation. Forklift AGVs are seemingly indispensable in warehouse automation as they can easily stack pallets, pick pallets stacked vertically in high-bay warehouses, and transport stacked pallets around the warehouse. The increasing density of warehouse operations and floor optimization necessitate using forklift AGVs to ensure adequate utilization of height without compromising warehouse operations and safety.

From an adoptability point of view, forklift type AGVs are closely in line with the emerging trend of smart warehouses. Clearly, the automobile industry, retail distribution businesses, as well as third-party logistics services provider businesses, are already leveraging such systems to address their handling requirements for high payload handling capabilities. As demand for automated storage systems continues to ascend, forklift type AGVs will again dominate the vehicle type segment.

The Laser Guidance segment is projected to witness the highest CAGR in the Automated Guided Vehicle during the forecast period.

Laser and vision technologies in the realm of navigation equipment are becoming the new standard in the AGVs marketplace owing to the sheer degree of flexibility offered. Unlike other traditional technologies employed in the standard AGVs, these technologies allow the machines to alter according to the changes in the way the environment is becoming.

However, the advent of artificial intelligence and sensor fusion has also improved the effectiveness of laser and vision guidance systems. These technologies enable real-time detection of various impediments, smart navigation and autonomous decision-making. As industries continue to adopt smart factory technologies the demand for flexible navigation solutions also increases. With that it is likely that laser and vision will remain dominant navigation solutions in AGV vehicles.

The Transportation & Distribution segment is projected to witness the highest CAGR in the Automated Guided Vehicle during the forecast period.

According to Transpire Insight, Transportation and distribution form the major application area under the Automated Guided Vehicle market, considering the need to maintain seamless internal material flow. Basically, AGVs have now become a major part of automating repetitive transport operations between a series of storage, production, and dispatch areas, thus resulting in considerable reductions in overall cycle times between these operations.

The increased use of e-commerce and omnichannel delivery or distribution has created a pressing need for rapid and effective logistics services. The use of AGVs is helpful in facilitating continuous movement of materials and high-volume order fulfillment without compromising its accuracy. The operation of these machines around the clock is also beneficial as it is in line with growing and increasing demands. The demand for transportation and distribution is likely to remain the major driver of the use of AGVs.

The Manufacturing segment is projected to witness the highest CAGR in the Automated Guided Vehicle during the forecast period.

Among the major end users of Automated Guided Vehicles (AGVs) is the manufacturing industry due to its high requirements for complexity in material handling processes. This sector encompasses various segments of industry, including automotive, electronics, and heavy machinery manufacturing, wherein material handling processes are critical for maximizing the efficiency of workflow. Through the application of AGVs in material handling processes, production activities can be carried out with less reliance on manual labor and to the maximum extent of minimizing downtime in production processes. This helps in integrating these processes with various systems for managing production processes as well as enterprise resource planning systems for minimizing the risks of shortages in various levels of production activities. Furthermore, this system also helps in maintaining safety requirements for the workplace as per the safety standards of various industries

Also, the adoption of AGVs in the manufacturing industry can be ascribed to their flexibleness, expandability, as well as their capacity to respond to changing manufacturing requirements without further infrastructural expansions or additions. AGVs can be utilized for various functions, including supporting the production process in an assembly line as well as warehouse-to-floor transport, thereby promoting improved efficiency in the entire process. Moreover, in recent times, augmented investments in the realization of Industry 4.0 are also propelling the adoption of AGVs in the manufacturing industry, as it would promote improved productivity in addition to maintaining a competitive advantage over competitors.

The North America region is projected to witness the highest CAGR in the Automated Guided Vehicle during the forecast period.

North America is at a leading position in the Automated Guided Vehicles Market owing to its progressive and highly developed infrastructure. The region is also focusing on automation and its application in industries. The industries of North America are increasingly embracing AGVs not only for enhancing operational efficiencies but also to ensure safety at work areas. The high labor costs of the countries of North America are also contributing to the increasing demand for AGVs as these vehicles ensure maximum utilization of production capacity without relying upon human effort to sustain production output. Organizations of North America are also focusing on implementing Smart Manufacturing and Industry 4.0 technologies and are using AGVs with Warehouse Management Systems, Manufacturing Management Systems, and Enterprise Management Systems for real-time tracking and end-to-end supply chain visibility. North America is another key market for AGVs due to the rise in the popularity of electronic commerce in the region. Similarly, the increased growth in logistics network infrastructures in the North American region favors the deployment of AGVs in the region. Moreover, the government in the North American region favors the adoption of automation technologies. Thus, the increase in awareness related to the safety features of AGVs would further maximize the profitability to the vendors in the North American region. Hence, the North American region would be the most lucrative market in terms of AGVs. Advanced technologies in the North American region would further intensify the growth in the North American region.

Key Players

The top 15 players in the Automated Guided Vehicle market include Toyota Industries Corporation, Daifuku Co., Ltd., KION Group AG, Jungheinrich AG, and Dematic Group. Other prominent participants such as SSI Schaefer Group, Murata Machinery, Ltd., Mitsubishi Logisnext Co., Ltd., Hyster-Yale Materials Handling, Inc., Seegrid Corporation, KNAPP AG, E&K Automation GmbH, Rocla Oy, BALYO SA, and Omron Corporation.

Drop us an email at:

Call us on:

+91 7666513636