Market Summary

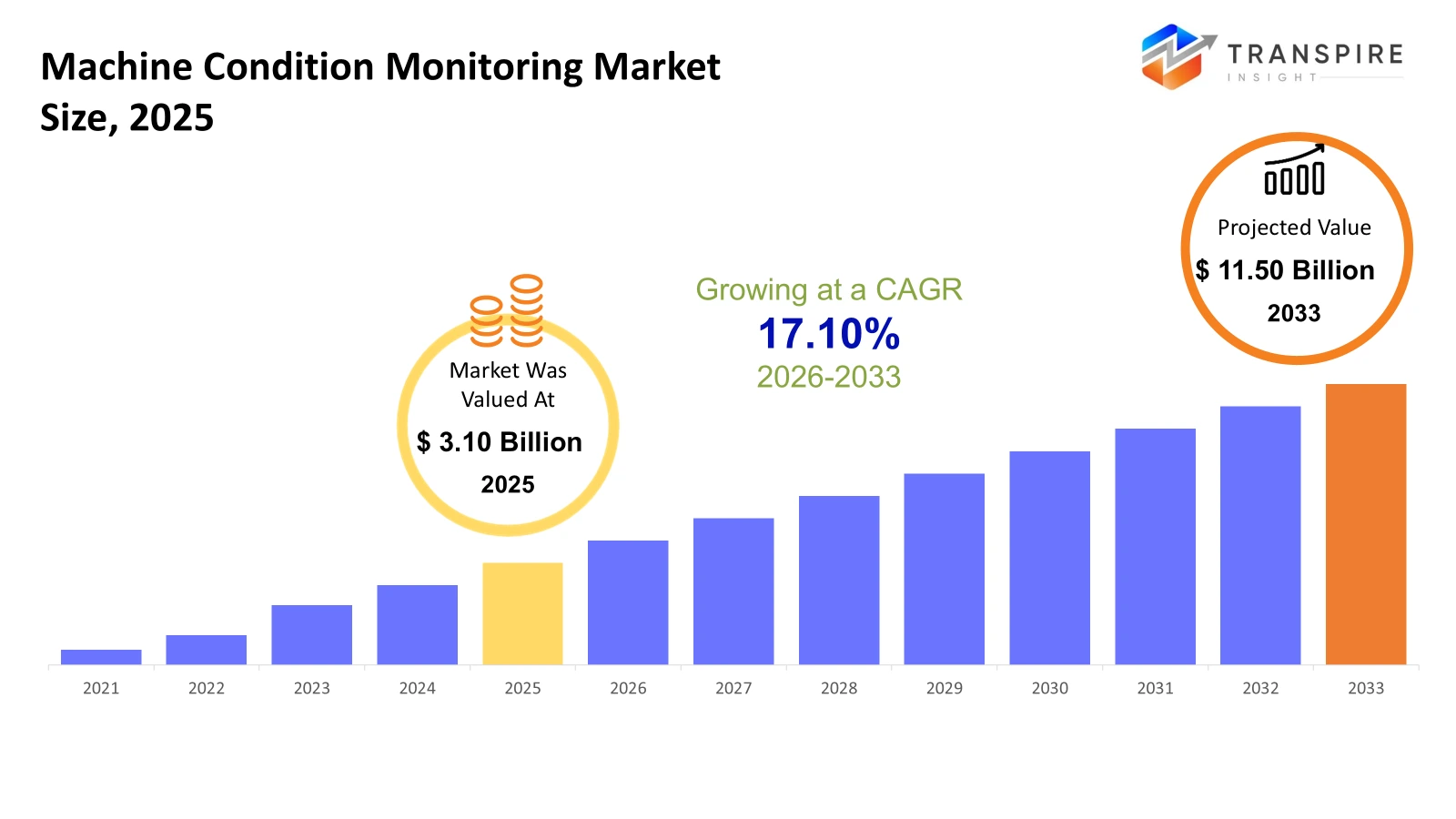

The global Machine Condition Monitoring market size was valued at USD 3.10 billion in 2025 and is projected to reach USD 11.50 billion by 2033, growing at a CAGR of 17.10% from 2026 to 2033. The market for machine monitoring is growing because more industries that rely on equipment are finding ways to predict when machines will break down. This way they can fix them before things go wrong. They lose money. The demand for machine monitoring is going up. This is because factories are using automation and new technology that needs to be watched all the time and analyzed. Factories need to analyze a lot of data. Also, tougher safety rules mean businesses have to buy machine monitoring systems. Machine monitoring systems help companies. Using cloud platforms and artificial intelligence to find problems helps companies like these expand in a way that's easier to manage. This does not cost a lot in the run, which keeps the market for machine monitoring growing steadily. The market, for machine monitoring is really growing because of this.

Market Size & Forecast

- 2025 Market Size: USD 3.10 Billion

- 2033 Projected Market Size: USD 11.50 Billion

- CAGR (2026-2033): 17.10%

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

To learn more about this report, Download Free Sample Report

Key Market Trends Analysis

- North America is still in the lead when it comes to using this stuff. They are really into automation in factories. They started using maintenance a long time ago. They spend a lot of money in the oil industry, gas industry and power industries. The rules and regulations, in these industries help push companies to invest in monitoring systems.

- In North America the United States is the user of technology the United States has a lot of factories and the United States uses a lot of energy from shale. The United States also has a lot of factory technology and the United States is always getting new things. There are companies in the United States that help other companies with technology and these companies in the United States want to work smarter so they always try to make their systems better and add more data analysis to their work, with technology and the United States companies keep using more technology.

- Asia Pacific is growing the fastest because China, India, Japan, and South Korea are expanding their manufacturing. More factories, better infrastructure, and knowing why it’s well to keep things maintained are causing more folks to use monitoring systems.

- Hardware is still the choice because people want vibration sensors, data collection units and monitoring devices that are always in place. More factories are using devices and buying advanced sensor equipment.

- Vibration Monitoring is the widely used method as it can detect equipment failure early especially for things with moving parts. It is affordable, accurate and works with automated diagnostic tools making it the preferred method, for major industries.

- Online or Continuous Monitoring is the top choice for keeping an eye on things because companies need real-time info and want to supervise equipment remotely. IoT systems are getting more popular, which beefs up the continuous flow of data and the ability to guess when things might fail.

- Oil & Gas is the biggest industry using this because they have very valuable equipment in tough spots. Avoiding equipment failures and cutting down on downtime in their operations keeps them spending money on monitoring tech.

The machine condition monitoring market involves tech that checks how well industrial machines are running by constantly or regularly looking at their data. These setups use sensors and tools to grab data, along with programs that look at things like vibration, temp, oil state, and how motors are working. The point is to spot early warning signs of damage, which helps cut down on unexpected stops and makes equipment last longer. Lots of companies are using these tools to switch from just fixing things when they break to guessing when they might break and fixing them beforehand.

The market's getting bigger because factories are using more automation and new tech. As factories and energy plants go digital, they really need ways to watch things in real-time and study data from one spot. Cloud setups and computer intelligence also make it easier to grow and check on machines from afar. Industries that cost a lot to run, like oil, gas, power, and big factories, are the main users because they can't risk things going wrong.

In terms of areas, North America is doing well because it's got good tech and rules to follow. Asia is growing fast because it's building up its factories and basic systems. We can expect the market to keep growing as we get better sensors and software for checking data.

Machine Condition Monitoring Market Segmentation

By Offering

- Hardware

Hardware's a big deal 'cause sensors, data units, and analyzers grab machine info right away. Industries are getting automated, and everyone wants to know when machines might break down, so they keep spending money on tough, top-notch monitoring stuff.

- Software

More folks are using software since analytics tools now give predictions, show data visually, and work smoothly with the Internet of Things and cloud stuff. Cool algorithms and remote monitoring help things run well, so software is key for keeping machines in good shape.

- Services

Services such as installation, tune-ups, repairs, and checking things remotely are absolutely crucial in getting the most out of these systems. Companies want experts to help ensure that everything is reliable, doesn’t fail, and has a long life. This is why there is always a demand for these service jobs.

To learn more about this report, Download Free Sample Report

By Monitoring Technique

- Vibration Monitoring

Vibration monitoring leads as Keeping an eye on vibrations. Good way to spot problems early in machines that spin and other important stuff. It’s super accurate, doesn't cost a ton, and works with computers, so factories, power plants, and oil companies all like it.

- Oil Analysis

Oil analysis is essential for monitoring lubrication, Checking oil is key to seeing if it's still good and clean, which stops machines from wearing out or breaking. People are getting smarter about keeping things in good shape, so they use this trick a lot to keep machines running smooth.

- Thermography

Using heat cameras can show you if anything's getting too hot, which can point to electrical or mechanical issues. Since you don't have to touch anything and can see problems right away, it's great for keeping things safe, mostly in energy, factory, and big industry places.

- Ultrasound Monitoring

Listening for strange noises using ultrasound waves is very helpful in detecting leaks, friction, and machine malfunctions quickly, providing you with information on how to repair things before they break down. It is very effective in testing hard-to-reach equipment, making things more reliable and preventing unexpected shutdowns in factories.

- Motor Current Analysis

Just looking at how much electricity the motors are using can help diagnose mechanical and electrical issues. Because you don't have to physically be in contact with the machine, you can monitor the important stuff at all times, which saves energy and keeps everything running smoothly.

By Monitoring Process

- Online / Continuous Monitoring

Portable monitoring provides flexibility for scheduled inspections and targeted diagnostics. Its cost-efficiency and suitability for dispersed or smaller assets make it essential for industries with varying equipment types and limited continuous monitoring infrastructure

- Portable / Periodic Monitoring

On the other hand, portable monitoring is great when you need to check things out on a schedule or take a closer look at specific issues. It's cheap and works well for equipment that's spread out or not that big. So, it's a must-have for industries that have all sorts of equipment and can't keep constant tabs on everything.

By End-Use Industry

- Power Generation

It is very important to keep an eye on things for power plants to ensure that the turbines, generators, and other equipment are running well. This will ensure that the power is on and that there are fewer repairs needed. Therefore, it is important to check the status of equipment.

- Manufacturing

Factories depend on tracking machine conditions to make production faster, cut down on surprise breakdowns, and keep machines running longer. Lots of automation and tough competition mean they really need to predict when maintenance is needed.

- Automotive

Car companies use monitoring on assembly lines, robots, and other key gear. Predicting maintenance helps keep things running without stopping and makes sure the quality stays top-notch. This supports the efficient, automated way they build cars.

- Metals & Mining

In metals and mining, they have to monitor the heavy machines that take a beating. Spotting problems early stops big failures, keeps workers safe, and keeps things running in rough conditions.

- Chemicals

Chemical plants use monitoring to keep an eye on the pumps the compressors and the reactors. The chemical plants need the equipment to work without fail. The chemical plants want to lower risks. They want to follow safety rules. So the chemical plants need ways to check on the pumps the compressors and the reactors.

Regional Insights

North America's a pretty established market. They're big on automation, jumped on predictive maintenance early, and have tough regulations. The US and Canada are ahead in using real-time monitoring. Mexico's catching up as its industries get more modern.

Europe's growing at a good pace. Germany, the United Kingdom and France are taking the lead because their factories, energy companies and car industries in Germany the United Kingdom and France really need people to keep an eye on them all the time. Spain and Italy are trying to improve what they already have in place. The rest of Europe is also adding people to watch over industries in Europe like the ones, in Germany the United Kingdom and France.

Asia Pacific is growing the fastest. Japan, China, and South Korea are doing well because of huge industrial growth, smart factory projects, and government money. India, Australia, New Zealand, and the rest of the region are using more monitoring as their industries get up to date and they learn more about predictive maintenance.

South America's growing moderately. Brazil and Argentina are the main users of monitoring in energy and manufacturing. The rest of South America is an opportunity as they improve infrastructure and start new industries.

The Middle East & Africa are picking and choosing what to adopt. Saudi Arabia, the United Arab Emirates, and South Africa are focused on keeping their industries reliable and using their equipment better. The rest of the area is gradually adding monitoring as they modernize.

To learn more about this report, Download Free Sample Report

Recent Development News

- September 2025, Emerson announced the launch of Guardian™ Virtual Advisor, an AI‑powered software solution that combines deep domain expertise with natural language support to help industrial users rapidly evaluate and optimize automation and asset performance, enhancing operational resilience with advanced analytics.

- September 2025, GE Vernova (part of General Electric’s energy business) secured an order for onshore wind turbines in Germany, reinforcing its renewable energy footprint and associated monitoring/service solutions. The announcement highlights GE’s continued deployment of advanced turbine technologies and lifecycle services

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 3.10 Billion |

|

Market size value in 2026 |

USD 3.80 Billion |

|

Revenue forecast in 2033 |

USD 11.50 Billion |

|

Growth rate |

CAGR of 17.10% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

Emerson Electric Co., General Electric, Honeywell International Inc., National Instruments Corporation, SKF Group, Wilcoxon Sensing Technologies, Parker Hannifin Corporation, Rockwell Automation Inc., Schaeffler Technologies AG, Siemens AG, ABB Ltd., Azima DLI, ALS Limited, Fluke Corporation, Brüel & Kjær Vibro GmbH |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Offering (Hardware, Software, Services); By Monitoring Technique (Vibration Monitoring, Oil Analysis, Thermography, Ultrasound Monitoring, Motor Current Analysis); By Monitoring Process (Online/Continuous Monitoring, Portable/Periodic Monitoring); By End-Use Industry (Oil & Gas, Power Generation, Manufacturing, Automotive, Metals & Mining, Chemicals) |

Key Machine Condition Monitoring Company Insights

Emerson Electric is a big player in industrial automation and keeping an eye on how things are running. They've got a long history in engineering and a ton of products for industries like oil & gas, power, manufacturing, and chemicals.

What they do is keep tabs on equipment using things like vibration checks, heat scans, and AI through their Plant web and AMS Suite systems. This helps companies fix stuff before it breaks and run things better. Emerson's also been buying up companies like National Instruments and part of AspenTech to beef up their skills in getting data and building software, which is what everyone wants these days with IoT and cloud monitoring. They're all over the world and have the support to back it up, making them a main source for solutions, that help predict when machines need fixing.

Key Machine Condition Monitoring Companies:

- Emerson Electric Co.

- General Electric

- Honeywell International Inc.

- National Instruments Corporation

- SKF Group

- Wilcoxon Sensing Technologies

- Parker Hannifin Corporation

- Rockwell Automation Inc.

- Schaeffler Technologies AG

- Siemens AG

- ABB Ltd.

- Azima DLI

- ALS Limited

- Fluke Corporation

- Brüel & Kjær Vibro GmbH

Global Machine Condition Monitoring Market Report Segmentation

By Offering

- Hardware

- Software

- Services

By Monitoring Technique

- Vibration Monitoring

- Oil Analysis

- Thermography

- Ultrasound Monitoring

- Motor Current Analysis

By Monitoring Process

- Online / Continuous Monitoring

- Portable / Periodic Monitoring

By End-Use Industry

- Oil & Gas

- Power Generation

- Manufacturing

- Automotive

- Metals & Mining

- Chemicals

Regional Outlook

- North America

- United States

- Canada

- Mexico

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- United Arab Emirates

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636