Market Summary

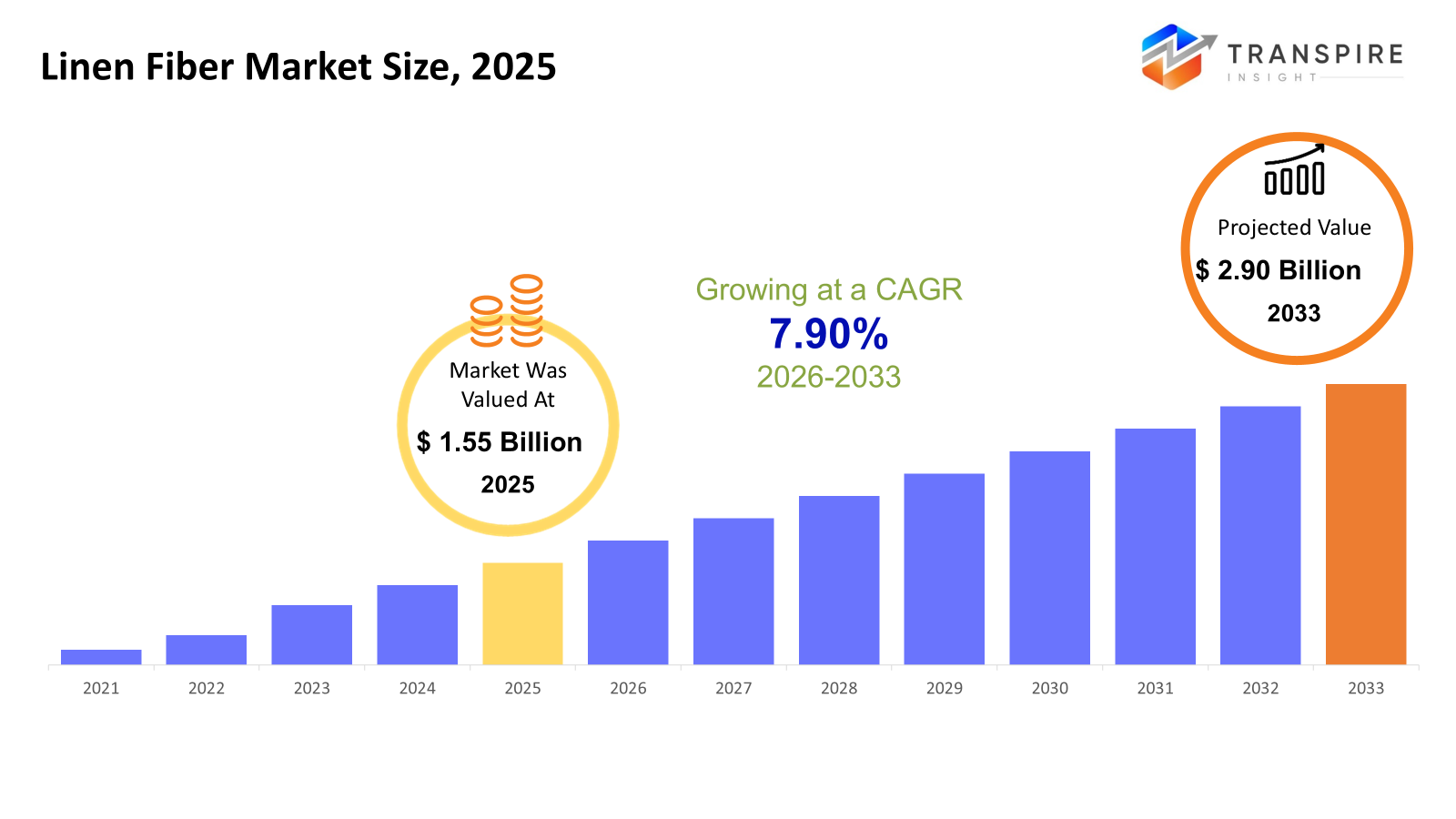

The global Linen Fiber market size was valued at USD 1.55 billion in 2025 and is projected to reach USD 2.90 billion by 2033, growing at a CAGR of 7.90% from 2026 to 2033. An increased demand from consumers toward sustainable and biodegradable textiles is one of the prime factors driving the CAGR of the linen fiber market. Growing regulatory scrutiny and emphasis on reducing the usage of synthetic fibers and minimizing the overall carbon footprint of an industry are further stimulating the adoption of linen fibers for various applications. Expanding the trend of eco-friendly fashionable wear, a rise in demand for home furnishings, and the increasing use of natural fiber composites in the automotive and construction sectors have further contributed positively to the long-term market outlook.

Market Size & Forecast

- 2025 Market Size: USD 1.55 Billion

- 2033 Projected Market Size: USD 2.90 Billion

- CAGR (2026-2033): 7.90%

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

To learn more about this report, Download Free Sample Report

Key Market Trends Analysis

- North America is further exemplifying persistent market growth with robust consumer awareness for sustainable textiles, premium apparel, and increasing demand for eco-friendly home furnishing textiles, with well-established infrastructure and innovation towards natural fiber technology supporting steady growth in linen fiber adoption.

- A significant contributor country, the United States boasts of large demand for sustainable fashion products, strong demand for natural fibers in high-end home furnishings and clothing, and the growing trend of eco-friendly materials in brands who wish to follow the path of sustainable practices.

- Asia Pacific indicates accelerated growth based on the expansion of textile manufacturing capacity, an increase in disposable income, and the rise of export-oriented apparel production, as countries such as China and India improve supply chains, considering the utilization of natural fibers to satisfy sustainability requirements of the international market.

- Long line linen fiber predominates because of its strength, durability, and suitability for high-quality end uses, gearing producers for the production of premium yarns and fabirc suited for the demand for breathable, long-lasting, and environmentally friendly clothing and home textiles.

- Wet spun processing presently occupies the top place due to the significant advantages that are possible with its employment for the production of good yarns with greater cohesion of the fibers as well as the smoothness of their surfaces.

- Fabric Form relishes a larger chunk of the market due to the finished state of the fabric and its increasing use in garments and home furnishings with the growing demand for such fabrics, especially with the increasing demand for comfort-based fabric forms and the introduction of more eco-friendly product lines by manufacturers.

- Textile and fashion industry remains to be the leading segment driven by growing global need for eco-friendly apparel, increasing adoption of natural fibers by fashion companies, and heightened consumer awareness about sustainability, longevity, and comfort factors related to daily wear and lifestyle products.

So, The linen fiber market comprises the production and usage of linen fibers from the stems of the flax plants, most commonly applied in the textile, home furnishing, and industrial sectors following their high durability, breathability, and degradability. Linen fibers are distinguished due to their renewable nature, simplicity, and humidity properties. Moreover, the trend of the linen fiber market is being dictated by considerations of sustainability. The market growth is facilitated by the global trend towards consumer and manufacturing practices that are environmentally friendly. Fibers of linen possess green credentials as an alternative to synthetic fibers. The expanding use in clothing, domestic textiles, and novel industrial applications in composite and insulation materials is widening the scope of the linen fibers market in developed and developing nations. The enhancement of technology in fiber processing, better cultivation of flax crops, and increasing interest in sustainable textile development are adding to the growth of the market. The industry players are shifting focus to better quality and efficiency in fiber processing to fulfill the growing demand from global markets. The increasing trend of using linen fibers for blended fibers and technical textile development is also adding opportunities for market growth.

Linen Fiber Market Segmentation

By Fiber Type

- Long Line Linen Fiber

Long line linen fibers are extracted from superior breed flax fibers. This type of fiber finds its primary application in high-end textiles due to its high tensile strength and smooth finish. This segment has great prospects as there is ever-increasing demand for eco-friendly as well as premium finish textiles for clothing and home linens.

- Short Linen Fiber

Short linen fiber, also called tow fiber, is derived as a by-product during the flax processing stage. This fiber is used in industrial fabrics. It is generally cost-effective and used in nonwoven forms, composites, and technical textiles. The demand for green products in reinforcement is currently motivating this segment.

To learn more about this report, Download Free Sample Report

By Processing Type

- Wet Spun

Wet spinning is largely utilized as a manufacturing technique for creating finer, more uniform, and strong linen yarns that may be employed for producing high-end clothing and homeware fabric materials. This technique also improves the bonding and smoothness of the fibers, facilitating the production of finer quality fabric materials.

- Dry Spun

Typically, dry spinning is employed to produce coarser yarns, which are used for industrial and heavy-textile applications. These processes are economically viable compared to other techniques and are often used to manufacture fibers; thus, industrial textile and blended yarn development remains crucial for this process.

By Form

- Yarn

Linen fibers in yarn form can be considered an important intermediate product used in the apparel, home textiles, and industrial fabric manufacturing sectors. This segment is primarily fueled by growing demand from textile makers who require natural and biodegradable materials, an alternative to synthetic fibers. Yarn consumption is fueled by sustainable fashion trends.

- Fabric

Linen fabric has a substantial market share; the primary reason for this is that the fabric is used to manufacture apparel, home furnishings, and lifestyle items. The fabric is breathable with good moisture absorption properties; hence, the market demand is expected to rise with the demand for premium and summerwear. Linen also has good durability. In addition to this reason, the demand is also influenced by the increase in natural fibers.

- Nonwoven

The use of nonwoven linen fibers is seen in technical textiles, insulation, and vehicular parts. This segment is affected by the increased interest in lightweight and biodegradable materials, especially among industrial applications. New composites of natural fibers continue to improve the extent of nonwoven linen usage.

By End Use Industry

- Textile & Fashion Industry

Textile and fashion is the largest consumer segment for linen fibers, driven by the rising demand for sustainable and breathable fibers. The natural look and longevity of linen fibers match the shift towards sustainable fashion. Premium apparel and seasonal clothing are some of the trends that are driving the growth for this segment.

- Home Furnishing Industry

The product segment of linen fibers finds application in home furnishing items including curtains, upholstery, bedding, as well as tablecloths. The product segment will gain from the rise in expenditure by consumers on home décor and green home furnishing items. The demand is high for premium as well as organic home textiles.

- Automotive Industry

For the auto industry, linen fibers are used as composite materials for vehicle interiors, particularly to minimize weight and maximize sustainability. For instance, auto companies are opting to use natural fibers to comply with environmental regulations, thus promoting sustainability. This idea, therefore, accounts for the expansion of linen fiber application, albeit at a slow pace.

- Construction Industry

Linen fibers are attracting increasing interest in several building applications, including insulation and environmentally friendly composite materials. The segment is supported by growing emphasis on sustainable building materials and green construction practices. Natural fiber-based solutions are increasingly considered alternatives to synthetic reinforcements.

- Others

Other end-use industries include packaging, handicrafts, and specialty industrial applications that value the properties of biodegradability and strength. Emerging niche applications continue to make demand for linen fibers more diverse. Innovation in natural fiber processing is expected to widen usage in other industries.

Regional Insights

North America, the United States, Canada, and Mexico, will show stable demand due to highly informed consumers about sustainable textiles and a very good demand outlook for high-value apparel and home furnishing products. Europe includes Germany, the UK, France, Spain, Italy, and the Rest of Europe. Europe continues to be one of the major markets owing to established flax cultivation, developed textile manufacturing infrastructure, and strong regulatory focus on sustainable materials. The fastest-growing region includes the Asia Pacific, with Japan, China, Australia & New Zealand, South Korea, India, and the rest of Asia Pacific, driven by expanding textile production, increasing textile exports, and consumer preference for natural fibers. China and India play vital roles not only as production centres but also consumption wise. South America, comprising Brazil, Argentina, and the rest of South America, sees sluggish growth through developing textile industries and a lesser uptake of eco-friendly materials. The Middle East & Africa region, which encompasses countries like Saudi Arabia, the UAE, South Africa, as well as the rest of the Middle East & Africa, is witnessing moderate growth driven by growth in hospitality segment, luxury textiles, as well as infrastructure development. Rising demand for luxury home furnishings and green products is gradually contributing to linen fiber demand.

To learn more about this report, Download Free Sample Report

Recent Development News

- February 2026, The Alliance For European Flax Linen & Hemp released an official press announcement pertaining to its attendance and participation at JEC World 2026, with a highlight on the greatly enhanced presence of the Bio-Materials Village with 14 members, including the main players on the linen fiber side, and the increased presentation of the industry’s offerings of natural fiber composites and innovations in the area of industrial applications.

- In March 2025, Libeco, a historic Belgian textile producer of linen fabrics, formally reveals its registration for JEC World 2025, featuring its cutting-edge linen fabrics for composites and launching its strategic collaboration with Terre de Lin, the producers of flax plants, for the creation of custom-made yarns targeting technical industries such as transport and construction. This press release highlights Libeco’s sustainable and innovative values.

(Source:https://www.libeco.com/uploads/general/heimtextil/2025-PRESS-RELEASE-Jec_250304_120904.pdf)

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 1.55 Billion |

|

Market size value in 2026 |

USD 1.70 Billion |

|

Revenue forecast in 2033 |

USD 2.90 Billion |

|

Growth rate |

CAGR of 7.90% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

Castellins NV, Procotex Corporation, COMLIN, FIR Group, DECOCK s.a., Fibrex NV, RE for FLAX Company, A&A Demeulenaere & Co NV, Van de Bilt Seeds and Flax BV, PROMAGRO, Linen of Desna, Noorlin, SWM, Libeco, and Safilin |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Fiber Type (Long Line Linen Fiber, Short Linen Fiber), By Processing Type (Wet Spun, Dry Spun), By Form (Yarn, Fabric, Nonwoven) and By End Use Industry (Textile & Fashion Industry, Home Furnishing Industry, Automotive Industry, Construction Industry, Others) |

Key Linen Fiber Company Insights

Castellins NV signified one of the most impactful companies within the linen fiber industry owing to its effective integration in the flax procurement, fiber production, and supply industries for textile and industrial purposes. The company currently commands a large and significant market share in the global industry related to the production of excellent quality fibers as well as its association with textile industry players. The competitive advantage of Castellins NV emerges from the consistent procurement of raw materials from flax regions of Europe, which follows increasing demand trends from players focused on providing sustainable products or options. The company profits from the increasing industry trend of natural fibers in automotive parts, clothing, as well as home textile applications.

Key Linen Fiber Companies:

- Castellins NV

- Procotex Corporation

- COMLIN

- FIR Group

- DECOCK s.a.

- Fibrex NV

- RE for FLAX Company

- A&A Demeulenaere & Co NV

- Van de Bilt Seeds and Flax BV

- PROMAGRO

- Linen of Desna

- Noorlin

- SWM

- Libeco

- Safilin

Global Linen Fiber Market Report Segmentation

By Fiber Type

- Long Line Linen Fiber

- Short Linen Fiber

By Processing Type

- Wet Spun

- Dry Spun

By Form

- Yarn

- Fabric

- Nonwoven

By End Use Industry

- Textile & Fashion Industry

- Home Furnishing Industry

- Automotive Industry

- Construction Industry

- Others

Regional Outlook

- North America

- United States

- Canada

- Mexico

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- United Arab Emirates

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636