Market Summary

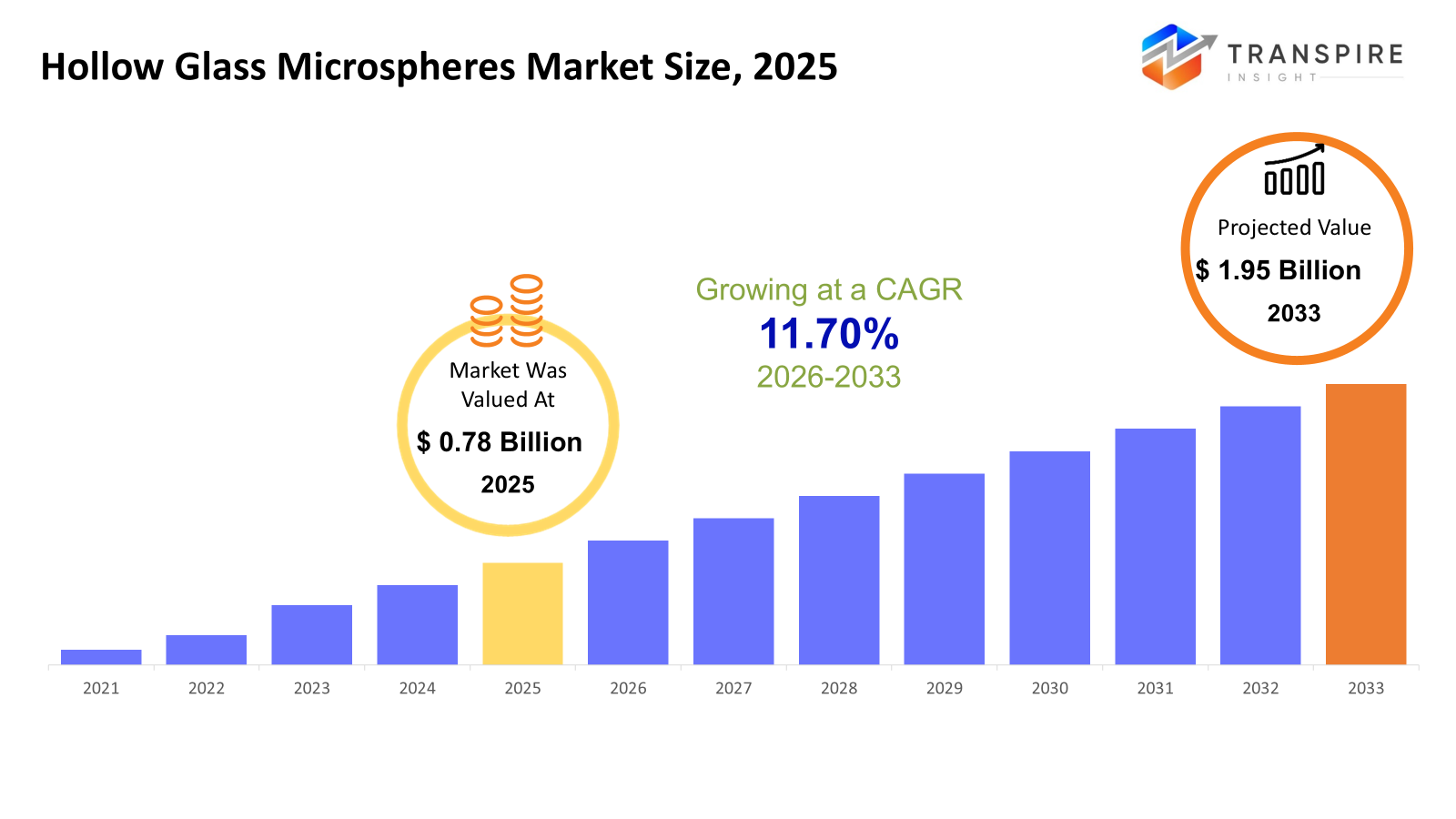

The global Hollow Glass Microspheres market size was valued at USD 0.78 billion in 2025 and is projected to reach USD 1.95 billion by 2033, growing at a CAGR of 11.70% from 2026 to 2033. Growth in the worldwide market for hollow glass microspheres comes mainly from a push for lighter yet sturdy materials. Because industries like building, car making, plane manufacturing, and energy extraction need better solutions, these tiny spheres are getting more attention. They boost heat resistance, cut down heaviness, and lift overall effectiveness - making them useful in complex mixtures and special surface layers. With cities expanding fast, plus a stronger interest in saving fuel and protecting nature, use of this material climbs even faster. What once seemed niche now fits into broader industrial shifts without drawing much notice.

Market Size & Forecast

- 2025 Market Size: USD 0.78 Billion

- 2033 Projected Market Size: USD 1.95 Billion

- CAGR (2026-2033): 11.70%

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

To learn more about this report, Download Free Sample Report

Key Market Trends Analysis

- The North American market share is estimated to be approximately 35% in 2026. Fueled by fresh spending on public works, builders across North America lean toward lighter, greener materials. Rules pushing cleaner projects help too; efficiency now matters more than ever before.

- Microspheres find growing use in the United States manufacturing, thanks to updated building standards backed by government support. Expansion in high-tech production lines helps drive adoption across new facilities nationwide.

- City growth speeds up across Asia-Pacific. Building projects pop up fast in this area. Car production rises sharply here. Factory work expands quickly, too.

- Low-Density Microspheres share approximately 35% in 2026. A shift toward lighter materials pushes microsphere use up. Because industries like building and car making need less dense options, these tiny spheres are spread into more products. Insulation work gains too, since weight matters there just as much. With every sector trimming bulk where possible, low-density beads find their place naturally.

- Because they make buildings lighter and hold heat better, tiny spheres are changing how construction materials work. These small particles help walls stay warmer without adding bulk. Their role grows as builders choose smarter ways to insulate. Lighter materials mean easier handling on job sites. Performance shifts when hollow beads mix into concrete or panels. Efficiency rises while weight drops across many new designs.

- Homeowners and builders now choose tighter insulation because green rules push less waste. Efficiency matters more since laws reward smaller power bills. New projects follow eco-methods, not just old habits. Tough codes shape walls, windows, floors - every piece counts. What once seemed optional is routine on job sites today.

Tiny glass bubbles float into view, light yet strong, as industries from building sites to space tech seek smarter materials. These small spheres, crafted from a mix of soda lime and borosilicate glass, bring less weight plus better insulation wherever they go. Cars roll more easily, rockets fly farther, pipes resist pressure, all because of what these specks can do. Energy savings catch attention now; factories and engineers take note across new economies and old alike. Performance matters more every day, pushing the use of such fine solutions without saying it loud. Growth creeps up quietly but surely where strength meets lightness in smart ways.

Lightweight microspheres lead in popularity because they cut down mass without sacrificing heat protection or strength. Even so, high-strength versions are seeing more use where toughness matters think deep wells, aircraft parts, and heavy machinery. Though small, these tiny glass bubbles adapt well, especially as coating tech improves and custom blends emerge. From stronger cement to high-end materials used in planes, their role keeps expanding quietly. Performance demands push changes; better surfaces help them fit into complex systems smoothly. What once seemed limited now appears almost everywhere that values lightness paired with resilience. Pressure-heavy fields adopt them steadily, drawn by reliability under stress. Innovation nudges them forward - not fast, but surely - into niches others can not reach. Material science shifts beneath the surface, guided by tiny spheres doing big jobs. One thing remains clear: lighter does not mean weaker anymore.

Construction materials top the list, since microspheres boost heat insulation while cutting weight and increasing fire and noise protection. Oil and gas follow close behind, relying on these tiny spheres to manage pressure, stabilize flow, and keep down density in drilling mixes. Lighter vehicles fly farther and burn less fuel, which explains why autos and aircraft now lean heavily on composite blends with microspheres. Coatings and paints find new uses too, drawing on durability and insulating perks that come built into each sphere. Medical fields tap the same particles for safe integration in biological settings, where steady structure and neutral reactions matter most.

As per Transpire Insights, within the hollow glass microspheres markets, North America stands out on the map because big construction projects often pop up there. Heavy investment in eco-friendly buildings helps too. Lightweight stuff shows up early in cars and homes thanks to industry habits. In that area, the United States moves ahead since policies promote energy-saving materials. Factories there also pick up new methods faster. Over in Europe, things have settled into place over time. Rules focused on lasting resources push change forward. Old structures get updates regularly. Building with less waste matters more every year. Meanwhile, the Asia-Pacific races ahead like few others. Cities rise quickly as people move in larger numbers. Industry grows at a speed unseen before. Materials that weigh less yet work better are in higher demand everywhere, from roads to power plants. Farther south and east, places like Latin America and parts of Africa begin to catch up slowly. As factories open and roads extend further, fresh uses appear bit by bit. Growth follows where steel goes up, and machines start running.

Hollow Glass Microspheres Market Segmentation

By Product Type

- High Strength Microsphere

When things need to hold up under stress, these tiny spheres step in. Built tough, they handle heavy loads without giving way. They keep their shape even when squeezed hard. In structures where failure is not an option, they play a quiet but vital role. Their strength lies in how they maintain form under strain.

- Low-Density Microspheres

Filling things gets easier when you go light; tiny hollow spheres make that happen by cutting heaviness. These little shells also trap air, which slows down heat movement across surfaces. Weight drops without losing shape, thanks to their structure spreading the load gently. Insulation climbs because pockets of still air form inside each rounded particle. Less dense means less strain on what holds them together. Tiny size lets them mix smoothly into different materials.

To learn more about this report, Download Free Sample Report

By Application

- Construction Materials

Concrete gains better insulation when lighter materials are used alongside stronger binders. Sealants perform longer if their structure resists cracking under stress. Composites achieve balance by mixing fibers that add toughness without increasing mass.

- Oil & Gas

Achieves stability underground when used in well construction, keeps things light yet sealed under force. Hollow glass beads slip into mud mixtures, changing how weight shifts during deep pushes. Temperature stays managed without extra gear tagging along. Pressure finds balance naturally, avoiding spikes that risk breaks. Drilling goes more smoothly because the flow resists sudden changes. Cement sets evenly since bubbles aren’t forming or collapsing nearby.

- Automotive & Transportation

From cars to trucks, lighter parts help save fuel while boosting speed. Built stronger yet thinner, these pieces cut down weight without losing power. Efficiency climbs when materials shift toward slim but tough designs. Moving faster becomes easier once bulk gets swapped for leaner builds.

- Aerospace & Defense

Flying machines and military gear rely on strong, lightweight materials made from modern composites. Strength stays high even when bulk goes down.

- Paints & Coatings

A fresh coat can hold heat better when built right. Smooth finishes often last longer in the sun and rain. Tiny changes in the mix help walls stay clean and strong. Quality shows up after months outside.

- Paints & Coatings

From health tools to targeted treatments, it plays a role in labs and patient care. Tiny systems help carry medicine where needed inside the body. Some devices assist doctors during complex procedures.

By End-Users

- Building & Construction

Construction relies heavily on light, heat-resistant materials. Because of this need, entire projects depend on such supplies. Structures require efficient insulation. Weight matters too - lighter components speed up assembly. So industries keep turning to these resources. Performance drives their constant use.

- Energy & Oilfield Services

Microspheres see more use when oil drilling picks up. Heavy-duty versions become essential during well construction tasks. Strength matters most in downhole conditions. Operations rely on tiny spheres to handle pressure. Demand climbs alongside activity in energy fields.

- Automotive & Aerospace

Heavy parts get lighter here. Performance climbs when composites take over. Materials change, results shift. Lightness becomes normal. Strong stuff replaces old standards. Weight drops without losing power. New forms rise where metal once ruled.

- Healthcare

A tiny sphere plays a role in healthcare tools, showing up where tests happen or studies take place. Devices meant for body-related tasks often include these small forms because they fit into complex systems. Work that explores new medical answers sometimes depends on their precise shape and size.

- Industrial Manufacturing

Built into tough industrial goods, microspheres show up in niche materials for heavy-duty uses. Slipping quietly into advanced manufacturing where strength and precision matter most.

Regional Insights

With the United Kingdom. pushing ahead, demand rises where performance matters most. Construction meets industry under one roof. Hollow glass microspheres find their place not just in cars but inside walls and pipelines too. Growth thrives wherever weight cuts matter, especially when rules nudge builders toward smarter choices. Policy shapes use patterns, quietly steering industries to adopt lighter solutions across fields like oil extraction and factory output. Progress moves fastest in regions tying efficiency goals to real-world builds.

Steady progress defines Europe's current phase, driven by tough rules on sustainability rather than rapid change. Retrofit projects keep gaining ground, especially where older structures meet modern demands. Lightweight solutions pop up often in cars and aircraft, pushing material choices forward. Germany, the United Kingdom, and France lead quietly, favoring tiny but strong spheres in walls, panels, and protective layers. These small components do heavy lifting without adding weight. Energy savings remain central, shaping how industries evolve their methods. Innovation isn’t sudden here - it builds slowly through practical upgrades. Growth holds firm, not because of spikes, but due to constant refinement behind the scenes.

Fastest gains show up across Asia-Pacific, thanks to swelling cities, factory expansion, and fresh builds going up fast. China, Japan, and South Korea lead the charge using tiny glass beads in buildings, vehicles, and power systems. India and parts of Southeast Asia follow close behind, pulled forward by housing booms, car production climbing, plus stronger interest in eco-smart supplies. Further activity stirs in Latin America along with Middle Eastern and African zones, where building work, factories, and energy needs slowly push demand higher.

To learn more about this report, Download Free Sample Report

Recent Development News

- April 27, 2021 – BASF and Omya enter global partnership on hollow glass microspheres.

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 0.78 Billion |

|

Market size value in 2026 |

USD 0.90 Billion |

|

Revenue forecast in 2033 |

USD 1.95 Billion |

|

Growth rate |

CAGR of 11.70% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

3M Company, SGS MINERALS, Sinosteel Corporation, AkzoNobel N.V., Omya AG, Wacker Chemie AG, Denka Company Limited, Toray Industries, Inc., Katalco Materials Inc., Nippon Glass Fiber Co., Ltd., Omya Microspheres, BASF SE, SCM Chemicals, Inc., Changzhou Shuanglin Microspheres Co., Ltd., Minnesota Mining & Manufacturing, PPG Industries, and Huizhou Yijie New Materials Co., Ltd |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Product Type (High Strength Microsphere, Low Density Microsphere), By Application (Construction Materials, Oil & Gas, Automotive & Transportation, Aerospace & Defense, Paints & Coatings, Medical & Biotechnology), By End-Users (Building & Construction, Energy & Oilfield Services, Automotive & Aerospace, Healthcare, Industrial Manufacturing) |

Key Hollow Glass Microspheres Company Insights

One name stands out when it comes to making tiny glass bubbles: 3M Company. Known worldwide, they build these small spheres with care, always pushing new ideas forward. Instead of just selling products, they deliver types that weigh less yet hold up under pressure. From roads to rockets, their materials find use in many places you might not expect. Performance matters most here, so each batch must last long and work well. Lightweight results come first, helping save energy across industries. Because they invest heavily in research, improvements are often made. Quality builds trust, which explains why customers keep coming back. Across continents, supplies move steadily through reliable channels. Strength in science gives them an edge few can match.

Key Hollow Glass Microspheres Companies:

- 3M Company

- SGS MINERALS

- Sinosteel Corporation

- AkzoNobel N.V.

- Omya AG

- Wacker Chemie AG

- Denka Company Limited,

- Toray Industries, Inc.

- Katalco Materials Inc.

- Nippon Glass Fiber Co., Ltd.

- Omya Microspheres

- BASF SE

- SCM Chemicals, Inc.

- Changzhou Shuanglin Microspheres Co., Ltd.

- Minnesota Mining & Manufacturing

- PPG Industries

- Huizhou Yijie New Materials Co., Ltd

Global Hollow Glass Microspheres Market Report Segmentation

By Product Type

- High Strength Microsphere

- Low-Density Microsphere

By Application

- Construction Materials

- Oil & Gas

- Automotive & Transportation

- Aerospace & Defense

- Paints & Coatings

- Medical & Biotechnology

By End-Users

- Building & Construction

- Energy & Oilfield Services

- Automotive & Aerospace

- Healthcare

- Industrial Manufacturing

Regional Outlook

- North America

- United States

- Canada

- Mexico

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- United Arab Emirates

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636