Jan 30, 2026

The report “Rotary Positive Displacement Pumps Market By Pump Type (Gear Pumps, Screw, Lobe Pumps, Vane Pumps, Peristaltic Pumps, Progressive Cavity Pumps, Others), By Capacity (Small Capacity, Medium Capacity, Large Capacity), By Technology (Energy?efficient / Smart rotary PD pumps, Materials / Construction Types, Pressure Ratings or Operating Conditions) and By End-Use Industry (Oil & Gas, Chemicals & Petrochemicals, Water & Wastewater Treatment, Food & Beverage, Pharmaceuticals & Biotechnology, Power Generation, Mining & Minerals Processing, Pulp & Paper and Other Manufacturing)” is expected to reach USD 13.80 billion by 2033, registering a CAGR of 7.50% from 2026 to 2033, according to a new report by Transpire Insight.

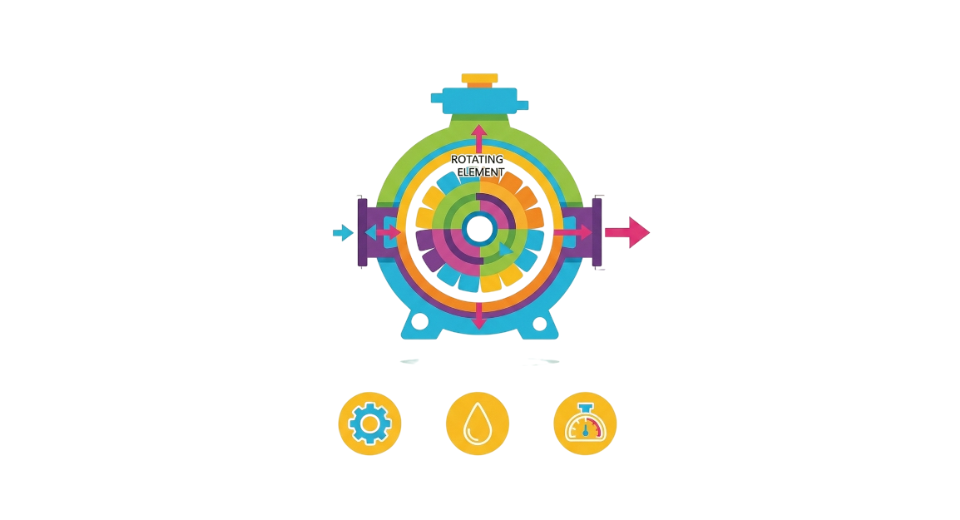

The global Rotary Positive Displacement (PD) Pumps Market is a key area in industrial fluid handling, consisting of pumps that deliver a fixed volume of fluid per rotation. These pumps which include gear, screw, lobe, vane, peristaltic and progressive cavity types are widely utilized in a variety of industries that demand accurate and reliable fluid flow. Applications include mining, pharmaceuticals, food and beverage, water treatment, power production, oil and gas and chemical processing. Rotary PD pumps are essential for contemporary industrial operations that require dependability and efficiency because of their innate capacity to handle viscous, abrasive and shear sensitive fluids. The significance for energy efficient solutions and growing industrial automation are fueling demand for rotary PD pumps. In order to achieve production and regulatory standards, industries are concentrating on maximizing process efficiency, reducing downtime and guaranteeing precise fluid management. IoT enabled and smart pumps with predictive maintenance are examples of technological innovations that are changing operational workflows, offering real time monitoring and cutting expenses. Industries that prioritize both sustainability and process optimization will find the market more appealing as a result of this trend.

Market expansion is severely impacted by regulatory compliance, especially in the pharmaceutical, food and beverage industries. In order to comply with strict FDA, GMP and ISO regulations, manufacturers are giving priority to hygienic low shear designs. In addition, new water treatment and infrastructure initiatives are broadening the range of applications for rotary PD pumps opening doors for reliable high capacity systems that can effectively manage a variety of industrial problems.

The Gear Pumps segment is projected to witness the highest CAGR in the Rotary Positive Displacement Pumps during the forecast period.

According to Transpire Insight, Because of their ease of use, robustness, and capacity to deliver steady, low-pulsation flow, gear pumps continue to rule the rotary PD pump industry. High-viscosity fluids are supported by their mechanical architecture, which makes them perfect for lubrication systems, chemical dosing and oil transfer. Gear pumps offer operational stability with little maintenance, appealing to sectors where uninterrupted fluid handling is vital. Growing demand in the food and beverage, chemical processing and oil and gas industries all of which depend on precise volumetric control is driving market expansion. Their market position is being further cemented by advancements in materials and design that increase wear resistance and prolong operational lifecycles.

Additionally, smart monitoring technologies are being included into gear pumps allows more real time performance improvement and predictive maintenance. Gear pumps are a popular option for firms looking for dependable, affordable fluid transfer solutions because of their operational efficiency, versatility across various fluid types and compatibility with digital monitoring systems. Their sustained dominance in the rotary PD pump market is demonstrated by their extensive adoption in both developed and developing economies.

The Medium Capacity segment is projected to witness the highest CAGR in the Rotary Positive Displacement Pumps during the forecast period.

Medium-capacity rotary PD pumps, normally handling flows between 101–1,000?m³/h, are getting acceptance across mid sized industrial operations. They are appropriate for chemical plants, water treatment facilities and food processing units because they provide a balance between performance, affordability and dependability. These pumps offer flexibility and scalability to satisfy changing industrial demands by supporting continuous operations and moderate fluid volumes. Medium-capacity pumps are the favored option for expanding industrial segments because to their controllable footprint, moderate energy consumption and operating versatility.

Furthermore, medium capacity pumps are becoming more and more popular for automated operations where accurate volumetric control and low maintenance needs are essential. Manufacturers are spending money on design upgrades to increase productivity, lower vibration and prolong service life. Medium-capacity rotary PD pumps continue to be essential to industrial process strategies because to the increasing demand for energy-efficient fluid handling solutions and optimal operational workflows, especially in areas undergoing infrastructure expansion and industrial modernization. Consistent market growth is fueled by their ability to connect small-scale precision and large-scale throughput applications.

The Energy?efficient / Smart rotary PD pumps segment is projected to witness the highest CAGR in the Rotary Positive Displacement Pumps during the forecast period.

According to Transpire Insight, Energy-efficient and smart rotary PD pumps are establishing as an innovative development in the market combining great performance with digital monitoring capabilities. These pumps use predictive maintenance analytics, variable speed drives and Internet of Things sensors to maximize energy efficiency, lower operating costs and avoid unplanned downtime. These technologies improve overall process efficiency while meeting sustainability goals which benefits industries like food processing, chemicals and oil and gas. The broader trend toward automation, real-time monitoring and process optimization is reflected in the deployment of smart pumps.

Also by lowering power usage and carbon footprint, energy-efficient designs address operating cost issues and regulatory demands. Through proactive maintenance warnings and system diagnostics, smart pumps increase longevity and dependability. Manufacturers of intelligent rotary PD pumps are seeing substantial development prospects due to the growing emphasis on digitization and environmental compliance. Because of their operational effectiveness, flexibility and capacity to satisfy changing industry norms, these solutions are becoming more and more popular in both developed and developing markets.

The Oil & Gas segment is projected to witness the highest CAGR in the Rotary Positive Displacement Pumps during the forecast period.

Due to the strong demand for handling viscous hydrocarbons, pipeline transfer and refinery operations, oil and gas remains to be the largest end-use segment for rotary PD pumps. Gear, screw, and progressive cavity pumps are frequently used to handle multiphase, high-pressure and high-viscosity fluids. The industry's worldwide growth especially in petrochemical facilities and pipeline infrastructure, creates a steady need for robust, high-performance pumps that can run continuously in difficult circumstances.

Operators may monitor pump performance, anticipate maintenance requirements, and maximize energy use by integrating smart monitoring systems. The oil and gas sector is a major force behind market expansion because rotary PD pumps continue to play a critical role in guaranteeing safe, effective and economical fluid handling as the world's energy demand rises and refineries expand or modernize operations.

The North America region is projected to witness the highest CAGR in the Rotary Positive Displacement Pumps during the forecast period.

North America has a mature market for rotary PD pumps, supported by well-established industrial sectors, including oil & gas, chemical processing, water treatment and power generation. The United States drives the region because to its massive refinery infrastructure, severe environmental and safety requirements and significant adoption of energy-efficient and IoT-enabled pump technologies. As a reflection of the modern industrial scene, manufacturers in this region prioritize operational efficiency, digital integration and product reliability.

Furthermore, the replacement and retrofit industry, where aging pump infrastructure necessitates improved, energy-efficient solutions has an impact on North American demand. In order to lower operating costs and avoid downtime, smart and predictive maintenance technologies are commonly used. This region’s stability, technological innovation, and regulatory compliance create a suitable environment for high-performance rotary PD pumps, ensuring continuous growth despite market maturity.

Key Players

The top 15 players in the Rotary Positive Displacement Pumps market include Flowserve Corporation, Grundfos Holding A/S, SPX Flow, Inc., Alfa Laval AB, Sulzer Ltd., KSB SE & Co. KGaA, Xylem Inc., Dover Corporation (PSG), ITT Inc., NETZSCH Pumps & Systems, Viking Pump, Inc., Ingersoll Rand Inc., Pentair plc, Atlas Copco AB, and Weir Group PLC.

Drop us an email at:

Call us on:

+91 7666513636