Market Summary

The global Warehousing Sorting Systems market size was valued at USD 3.15 billion in 2025 and is projected to reach USD 5.51 billion by 2033, growing at a CAGR of 7.23% from 2026 to 2033. The warehousing sorting systems market is expanding due to the surge in e-commerce and the need for faster, accurate order fulfillment. Automated and semi-automated systems reduce labor costs and improve efficiency in parcel sorting and returns management. Advances in conveyor and cross-belt technologies, coupled with growing adoption in logistics, retail, and healthcare sectors, are driving sustained market growth globally.

Market Size & Forecast

- 2025 Market Size: USD 3.15 Billion

- 2033 Projected Market Size: USD 5.51 Billion

- CAGR (2026-2033): 7.23%

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

To learn more about this report, Download Free Sample Report

Key Market Trends Analysis

- North America market share estimated to be approximately 35% in 2026. Automation in warehouses spreads fast across North America. Rising demand for same-day deliveries pushes change. Expensive labor speeds up the shift. Existing transport networks make it easier. Smart machines now handle more sorting tasks.

- Fueled by surging online shopping, America sees a push toward faster shipping methods. Sorting hubs now favor cross-belt setups over older models. Growth in outsourced delivery services drives demand for flexible infrastructure. Conveyor networks spread through warehouses at an increasing pace.

- Fueled by rapid e-commerce expansion, countries in the Asia-Pacific region see rising needs for fast, low-cost sorting tech. Industrial shifts push system upgrades, not just in big cities but in rural zones too. Smart warehouses grow quickly, driven more by practical gains than trends. Efficiency matters most where volume spikes unpredictably. Even mature markets reshape operations under pressure to keep pace. New demands emerge less from policy and more from daily logistics hurdles.

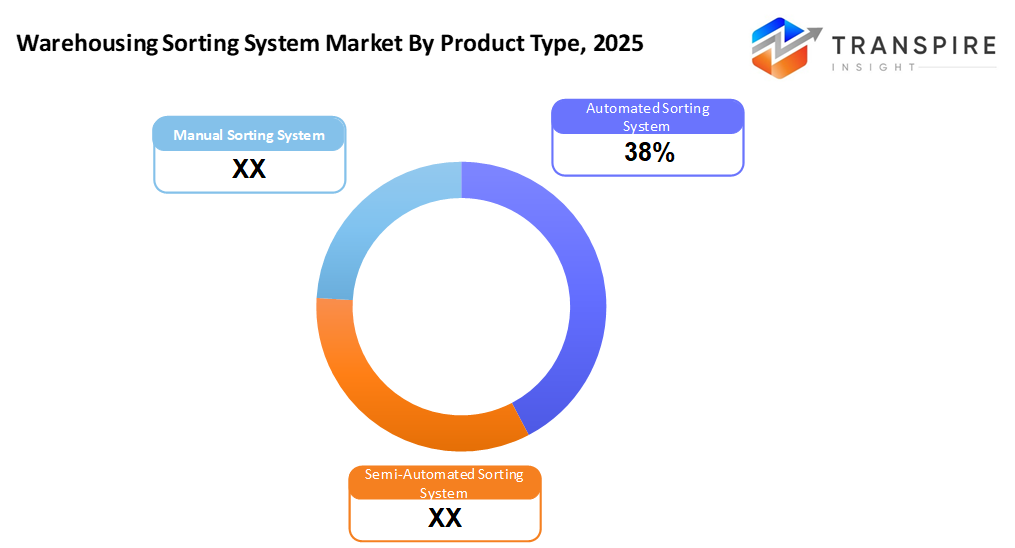

- The Automated Sorting System shares approximately 39% in 2026. Warehouses now move faster than ever, due to machines that sort packages without help from people. Speed matters more every day, so companies choose automation to keep up with demand. Instead of waiting for manual checks, items flow through smart systems that cut down delays. Efficiency is not just a goal -it shows up in how quickly orders ship out. As online shopping grows, these automated setups become essential for staying responsive. Time saved during sorting adds up across the entire delivery chain.

- Besides speed, these sorters adapt well when packages differ in size or shape across busy shipping centers. Their precision stands out where order mistakes cost time. Flexibility becomes key whenever parcel types keep changing throughout the day. Most big online shopping warehouses rely on them simply because they rarely slow down.

- Holding the largest portion of the market, parcel sorting thrives as online shopping pushes more deliveries through courier networks. Faster shipping expectations shape how packages move each day. Growth here ties closely to rising requests for one-day or next-morning arrival times.

- Online shopping and stores now lead the pack, growing quickly because sellers are putting big money into machines that sort packages fast. This helps them ship orders from multiple sources without delay, keeping up with how people buy things today.

Right now, more places around the world are using smart ways to sort items in storage buildings. Machines that move boxes and packages faster are becoming common in big hubs where things get shipped out. Some setups run fully on their own, others need people to help, while some still rely only on workers, but each kind helps cut down mistakes and keeps things moving smoothly. Computers that learn, robotic arms, and devices connected through the internet are giving these systems better accuracy and room to grow. Efficiency gets a boost when tech adapts quickly to changing needs inside today’s delivery networks.

A surge in online shopping and blended retail models demands quick, precise sorting at high speed. Because orders pile up fast and deadlines shrink, slow systems just do not keep up. Now, add fewer workers available, pay going up, and more packages flowing through delivery networks. These pressures push warehouse managers toward machines that sort with less human effort. Efficiency becomes essential, not optional. Timely shipping depends on it.

North America and Europe stay ahead because their transport networks are strong, warehouses often use automated tools, and deliveries must meet tight standards. What stands out is the United States's big online shopping sector and outsourced logistics fuel demand for modern sorting gear, including cross-belt setups and moving belt arrangements. Over in Asia-Pacific, change moves fast. Industrial growth picks up speed there, internet shopping spreads wider, and nations such as China, India, and Japan pour money into intelligent storage tech. That stretch of land now grows quicker than others in this field.

Right now, people buying things online push the biggest need for these systems. Still, companies moving goods and making products start using them more often because they save time and money. New tricks like smarter sorting with artificial intelligence help too. Designs that fit together like building blocks make setups easier. Connecting these machines to warehouse software boosts what they can do. Performance gets better without slowing down later on. Growth looks steady ahead simply because everything works better together now.

Warehousing Sorting Systems Market Segmentation

By Product Type

- Automated Sorting Systems

Machines handle sorting tasks start to finish, needing almost no human help. These setups push speed while keeping mistakes rare. Efficiency climbs when people step back. Precision stays high because robots repeat moves exactly. Fewer hands mean less downtime. Tasks flow without pauses. Accuracy improves over time. Speed does too. Little room is left for error. Operations run smoother than before.

- Semi-Automated Sorting Systems

Some sorting setups mix machines with people handling items, splitting tasks between them. Efficiency gets a boost without spending too much on full automation. Workers step in where flexibility matters most.

- Manual Sorting Systems

Folks handle the picking by hand when machines aren’t around. These setups show up most where space is tight or orders are few. Workers move item by item, guided only by checklists or memory. Efficiency depends entirely on how sharp each person stays during the shift. Mistakes creep in faster when fatigue sets in late afternoon.

To learn more about this report, Download Free Sample Report

By Technology

- Conveyor-Based Sorting System

A steady stream of packages glides along rollers, carried forward by moving belts through the building. One after another, objects shift direction at timed points, guided without pause across long stretches of track.

- Tilt Tray Sorters

These sorting machines tilt their trays to send packages down specific slides or into set containers. Moving parts shift direction so parcels land where needed without manual handling. Gravity helps carry each piece once the tray angles sideways. Items roll off when the system decides on a new path. Direction changes happen quickly between stops.

- Cross Belt Sorters

Speedy cross belt sorters guide packages exactly where they need to go. Each one carries its own tiny conveyor strip. These small belts shift items sideways at just the right moment.

- Push Tray Sorters

A sudden nudge moves each item aside. These sorters guide things off the central path with small arms. One lane gets a package when the machine shifts it sideways. Direction depends on where it needs to go. Movement comes from steady pressure at just the right moment.

- Others

Built for unique tasks, these cover options like bomb-bay setups, shoe systems, or mixed sorting methods. Their design fits particular mission demands.

By Application

- Order Fulfillment

Fulfilling orders means getting items ready for customers by sorting them fast. Speed matters when pulling correct goods off shelves one after another. Accuracy shows up most in how well each package matches what was requested. Moving things right keeps delays low through careful handling step by step.

- Parcel & Package Sorting

Sorting parcels means moving boxes where they need to go fast, without delays. A smooth flow keeps things on track. Each item gets checked and then sent forward. Direction matters just as much as speed. Mistakes slow everything down. Clear paths help avoid confusion. Packages shift from one point to another with purpose. Efficiency comes from a steady rhythm. Getting it right beats rushing through.

- Returns Management

Sorting what comes back, some items go straight to shelves, others get fixed up before reuse, and a few travel backward through supply chains.

- Inventory Management

Sorting items neatly helps find them fast when needed. Keeping track of each product type makes restocking simpler. Labels and order matter most behind the scenes. Efficiency grows when every piece has its place

. By End-Users

- E-Commerce & Retail

Sorting machines help shops handle lots of orders. Big websites rely on them when sales spike. Systems move packages fast without delays. Workers get support during busy seasons. Orders flow smoothly thanks to automated setups.

- Logistics and Third-Party Warehousing

Faster sorting systems help third-party warehouses manage work for different customers at once. Machines organize goods so deliveries stay on track without delays piling up.

- Manufacturing

Out there, factories move parts into groups this smooths out how things get built and shipped. Piles of pieces find their place before anything rolls off the line. Sorting happens early, so nothing jams up later on. Finished goods wait in order, ready to go when needed. Everything lines up just right because chaos slows everything down.

- Food & Beverages

Pick through sealed food and drink packages where cleanliness matters. Trace each item carefully after sorting them apart. A clean path stays clear only when every piece moves right.

- Pharmaceutical and Healthcare

Fine-tuned separation for medicines where precision matters, rules must be followed. Processing pills and healthcare supplies with care, each step built around exactness.

Regional Insights

Few places run ahead quite like North America and Europe when it comes to sorting tech in warehouses, strong delivery networks, widespread online shopping, and a head start on machines doing the work have pushed things forward. The United States plus Canada stand out across that region, home to big-name retailers, digital sellers, and shipping firms pouring resources into smart sorters and conveyor belts that shift packages sideways. Meanwhile, down south, nations like Mexico and others through Central America inch closer each year, their storage hubs slowly upgrading how they move goods. Over in Europe, powerhouses such as Germany, Britain, France, and Italy dominate activity thanks to vast supply chains and rules pushing companies to clean up how they deliver. Places such as Spain, Poland, and those farther north see quiet but sure momentum building behind robot-assisted spaces tucked inside modern depots.

Out in Asia-Pacific, warehouses are speeding up fast industrial growth pushes change, online shopping spreads wider, while smarter storage spaces become more common. Leading nations like China, India, and Japan set the pace; their big distribution hubs and transport firms are now turning to quick, robot-driven sorting tools. Behind them, places such as Indonesia, Vietnam, Thailand, and South Korea start seeing shifts too, as more digital buying brings pressure, businesses respond by upgrading with partial or full automation inside their storage sites.

Down south, places like Brazil and Mexico lead the way as tech use grows alongside shopping and online sales. Following behind, nations such as Argentina, Chile, and Colombia slowly began using more advanced sorting systems. Over in the Middle East and Africa, big players Saudi Arabia, the United Arab Emirates, and South Africa are putting money into smarter warehouses and transport networks. These efforts aim to keep pace with rising business demands. Elsewhere across that region, many areas still lag but show signs they could grow later on. Progress moves slowly now, yet room for change is clear as upgrades continue.

To learn more about this report, Download Free Sample Report

Recent Development News

- September 4, 2025 – Interroll acquired Dutch startup Sortteq to grow sorting technology.

(Source:https://www.mmh.com/article/interroll-acquires-sortteq-expands-sorting-technology

- May 1, 2025 – Dematic launched next-generation sorting technology to enhance logistic efficiency across Southern Asia.

- April 15, 2024 – Geek + Collaborated with Toll Group to launch its first robotics sorting warehouse in Korea.

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 3.15 Billion |

|

Market size value in 2026 |

USD 3.38 Billion |

|

Revenue forecast in 2033 |

USD 5.51 Billion |

|

Growth rate |

CAGR of 7.23% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

Armstrong Ltd, Atmos Systems, Beumer Group, Craftsman Storage Systems, Dematic, Falcon Autotech, Fortna, Interroll, Daifuku CO. Ltd, Murata Machinery, TGW Logistics, Gebhardt Intralogistics, Suzhou Apollo, Numina Group, Smartlog Group, Precision Warehouse Design, and others. |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Product Type (Automated Sorting Systems, Semi-Automated Sorting Systems, Manual Sorting Systems), By Technology(Conveyor-Based Sorting Systems, Tilt Tray Sorters, Cross Belt Sorters, Push Tray, Others), By Application (Order Fulfillment, Parcel & Package Sorting, Returns Management, Inventory Management), By End-Users (E-Commerce & Retail, Logistics and Third Party Warehousing, Manufacturing, Food & Beverages, Pharmaceutical & Healthcare) |

Key Warehousing Sorting Systems Company Insights

A global presence defines the Dematic company. Instead of just moving goods, its systems organize them with precision. Efficiency comes through smart machines working nonstop. That is what this company builds. Systems that sort packages at speed show up in big warehouses everywhere. Software runs quietly behind the scenes, making sure everything flows right. Some setups climb tall into the air, storing items on shelves that robots can easily access. Across nations far apart will find their gear running day and night. People order online, stores need stock, and factories ship out. This helps it happen smoothly. More than ten thousand workers design, install, fix, and upgrade these networks. A larger group owns them now, known for trucks and moving things in smart ways. New tools they make adapt quickly, some even learn how to do tasks better over time. Accuracy jumps when sensors guide each step without errors piling up. Flexibility stands out because parts can shift as business changes direction. Integration means different tech speaks clearly to one another. Efficiency grows not by luck but through constant small gains adding up. Warehouses transform from cluttered spaces into precise operations top to bottom.

Key Warehousing Sorting Systems Companies:

- Armstrong Ltd,

- Atmos Systems

- Beumer Group

- Craftsman Storage Systems

- Dematic

- Falcon Autotech

- Fortna

- Interroll

- Daifuku CO. Ltd

- Murata Machinery

- TGW Logistics

- Gebhardt Intralogistics

- Suzhou Apollo

- Numina Group

- Smartlog Group

- Precision Warehouse Design

- others

Global Warehousing Sorting Systems Market Report Segmentation

By Product Type

- Automated Sorting Systems

- Semi-Automated Sorting Systems

- Manual Sorting

By Technology

- Conveyor-Based Sorting Systems

- Tilt Tray Sorters

- Cross Belt Sorters

- Push Tray

- Others

By Application

- Order Fulfillment

- Parcel & Package Sorting

- Returns Management

- Inventory Management

By End-Users

- E-Commerce & Retail

- Logistics and Third Party Warehousing

- Manufacturing

- Food & Beverages

- Pharmaceutical & Healthcare

Regional Outlook

- North America

- United States

- Canada

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636