Market Summary

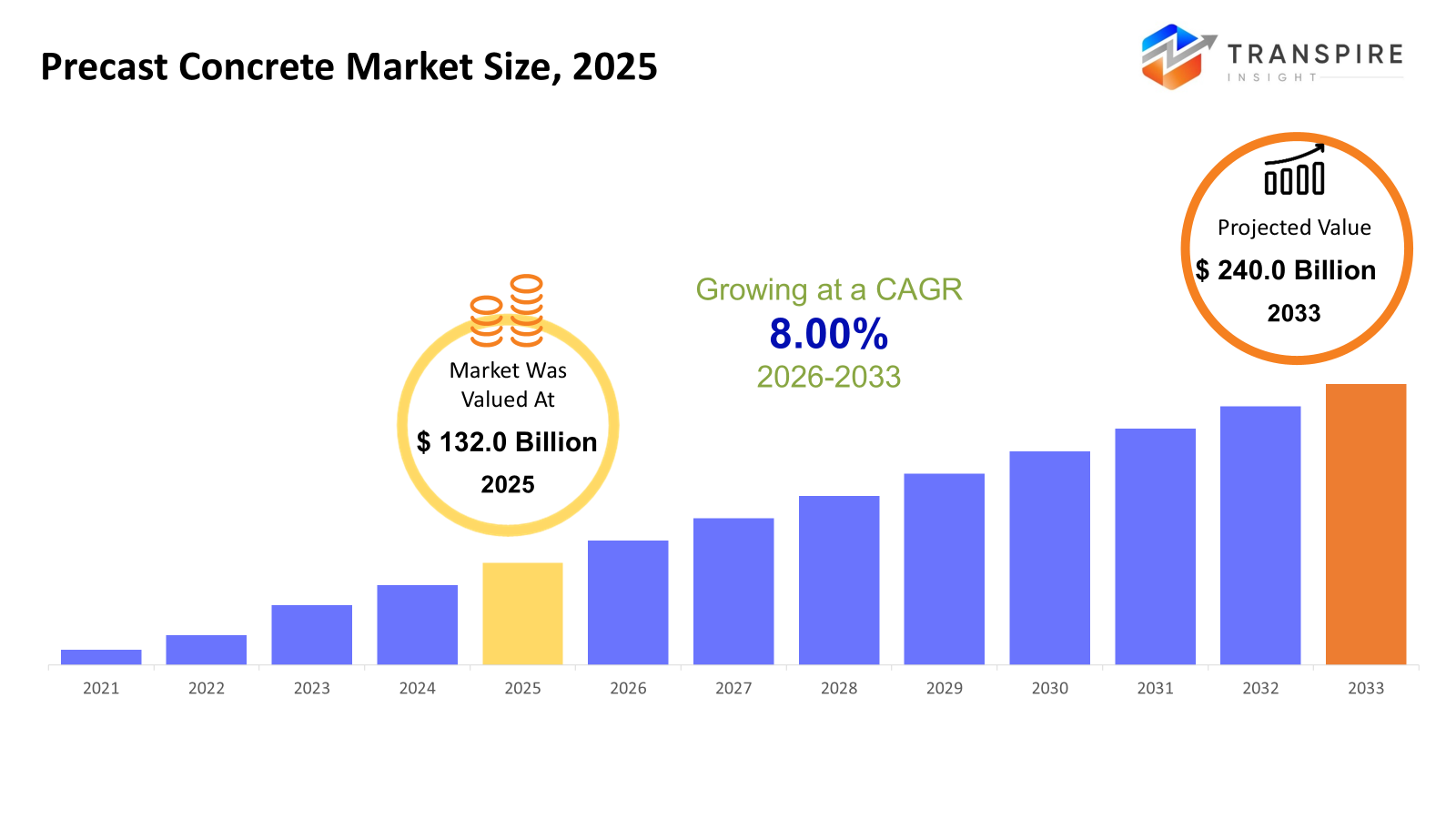

The global Precast Concrete market size was valued at USD 132.0 billion in 2025 and is projected to reach USD 240.0 billion by 2033, growing at a CAGR of 8.00% from 2026 to 2033. Large-scale infrastructure investments the need to shorten building timetables and growing urbanization are all contributing to the precast concrete market's steady expansion. Prefabricated solutions are becoming more and more popular among contractors due to growing labor shortages and escalating on-site construction expenses. Better precast manufacturing technologies and sustainability regulations are also bolstering long-term usage in both developed and emerging nations.

Market Size & Forecast

- 2025 Market Size: USD 132.0 Billion

- 2033 Projected Market Size: USD 240.0 Billion

- CAGR (2026-2033): 8.00%

- North America: Largest Market in 2026

- Asia Pacific: Fastest Growing Market

To learn more about this report, Download Free Sample Report

Key Market Trends Analysis

- Infrastructure rehabilitation, highway bridge replacements, and the growing use of off-site construction techniques are driving North America's strong momentum to address the skilled labor shortage, especially in commercial, industrial, and public infrastructure projects in urban and suburban areas.

- Because of federal infrastructure funding programs, growing warehouse and logistics construction, and the growing use of standardized precast components that enhance project predictability, cost control, and construction safety across large-scale developments, the United States continues to lead regional demand.

- With rapid urbanization, government-sponsored housing programs, metro rail projects, and industrial zone development, Asia Pacific continues to be the fastest-growing market. Japan is focusing on high-precision, seismic-resistant precast solutions, while China and India are driving volume demand.

- Slabs and floors, walls and panels, and pipes and culverts are the most popular product types because they are the most efficient to install and are essential for infrastructural, commercial, and residential projects that demand durability, speed, and constant quality control.

- As developers look for quicker project delivery, less material waste, and predictable prices, building type trends show a growing preference for modular construction systems, especially in high-density residential complexes, hotels, healthcare facilities, and student housing projects.

- While industrial applications gain pace due to the expansion of manufacturing plants, data centers, and logistics hubs worldwide, end-use trends are driven by infrastructure and residential projects, which are bolstered by public spending on transit networks and affordable housing programs.

So, The manufacturing and off-site production of concrete components that are transported and assembled at construction sites make up the precast concrete market. These features, which are intended to improve construction efficiency, quality uniformity, and structural performance, include structural, architectural, and infrastructure components. Because it can meet complicated technical needs while standardizing outputs, precast concrete is essential to modern building. The increasing need to expedite building timeframes without sacrificing durability or safety is driving market acceptance. Precast systems eliminate reliance on the weather, cut down on material waste, and increase worker productivity when compared to conventional cast-in-place techniques. These benefits are especially helpful in large-scale infrastructure projects, commercial structures, and residential constructions where delays and cost overruns present serious hazards. Innovations in digital production processes, reinforcing methods, and concrete compositions also assist the market. Design accuracy has increased and lifetime costs have decreased with the integration of automated production lines and Building Information Modeling (BIM). Precast concrete is becoming more and more strategically significant in global building ecosystems as governments and corporate developers place a greater emphasis on sustainability, durability, and quicker project execution.

Precast Concrete Market Segmentation

By Product Type

- Columns & Beams

Precast beams and columns are essential load-bearing components that are frequently found in high-rise residential, commercial, and industrial buildings. Faster installation, dimensional precision, and fewer on-site labor requirements are what drive their demand. Precast systems are very popular in North America and Europe due to labor cost concerns and structural standardization. Rapid urbanization and the growth of industrial facilities in Asia Pacific are driving demand.

- Girders

The main applications for precast girders are in infrastructure projects including metro rail systems, flyovers, and bridges. They are crucial for transportation infrastructure because of their capacity to span great distances without losing structural integrity. The Middle East and Africa, as well as Asia Pacific, have high demand, which is bolstered by government-funded infrastructure upgrade initiatives. Bridge replacement and highway restoration projects are still being adopted steadily throughout North America.

- Slabs & Floors

Precast slabs and floor systems are perfect for residential, commercial, and industrial buildings because they allow for quick construction cycles and better quality control. These products increase project efficiency by lowering the need for formwork and enabling simultaneous building processes. Due to advanced prefabrication techniques, Europe and North America have high penetration rates whilst Asia Pacific shows rising demand from large-scale residential and commercial buildings.

- Walls & Panels

Because of their higher thermal performance and design flexibility, precast walls and panels are being employed more and more for structural and architectural purposes. They are extensively used in institutional buildings, warehouses, and residential housing. Europe has high demand because of strict energy efficiency laws, whereas Asia Pacific and the Middle East gain from their appropriateness for large-scale commercial developments and mass housing.

- Pipes & Culverts

Infrastructure related to stormwater management, drainage, sewage, and water delivery depends on precast concrete pipes and culverts. Their long service life, corrosion resistance, and durability encourage wider adoption. Africa, South America, and Asia Pacific are all seeing rapid expansion, fueled by investments in public infrastructure and urbanization. The need to replace and renovate old utility networks remains constant in North America.

- Paving Slabs

Precast paving slabs are frequently utilized in public infrastructure projects, parking lots, pedestrian zones, and urban landscaping. Adoption in commercial and municipal developments is facilitated by their aesthetic variety and ease of replacement. Asia Pacific cities are rapidly using paving slabs for smart city and public space development projects, but Europe is in the lead due to massive urban regeneration activities.

- Staircases

Compared to cast-in-place options, precast staircases provide better site safety, faster installation, and consistent quality. They are extensively utilized in institutional facilities, commercial structures, and residential complexes. While demand is steady in North America and Europe, high-rise residential construction and standardized building designs are associated with growth in Asia Pacific.

- Others

Specialized precast parts designed for particular structural or decorative purposes are included in this section. The requirement for precisely engineered pieces and the ability to customize are what fuel demand. Due to the expansion of rail networks, railway sleepers are in high demand in Asia Pacific and Europe, while architectural precast parts are being utilized more frequently in high-end commercial and institutional projects worldwide.

By Construction Type

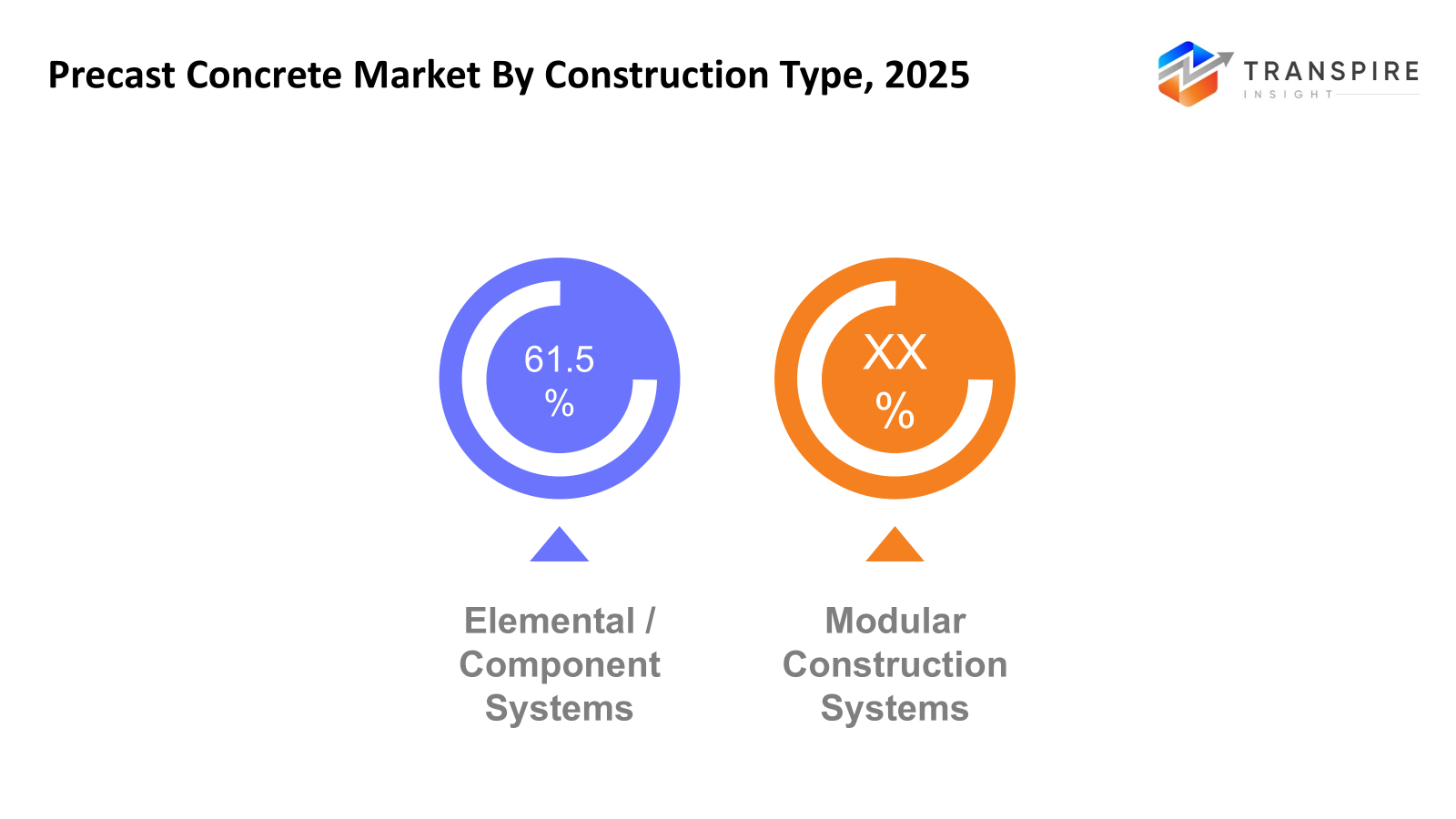

- Elemental / Component Systems

Elemental precast systems provide design and application flexibility by assembling individual structural components on-site. This method is frequently used in commercial, industrial, and residential construction, particularly when partial precast integration is desired. Due to their developed building ecosystems, North America and Europe dominate this market, while Asia Pacific exhibits growing use in mid-rise and industrial developments.

- Modular Construction Systems

Volumetric modules made off-site and quickly assembled at the project site make up modular precast systems. These systems increase quality consistency and drastically shorten building times. Housing shortages, labor shortages, and growing acceptance of off-site construction methods are the main drivers of the robust expansion seen in North America, Europe, and portions of Asia Pacific.

To learn more about this report, Download Free Sample Report

By End‑Use

- Residential Construction

In order to promote mass housing, affordable housing, and high-rise apartment buildings, precast concrete is being used more and more in residential construction. Adoption is fueled by advantages including construction speed, cost effectiveness, and consistency in quality. Large-scale urban housing initiatives in Asia Pacific drive demand, while precast is used in North America and Europe for multi-family and sustainable housing projects.

- Commercial Construction

Precast allows for quicker project delivery and consistent design in commercial settings such as offices, shopping malls, hotels, and medical buildings. Growing investments in mixed-use projects and commercial real estate are advantageous to the segment. Demand is still high in North America and Europe, but Asia Pacific is growing quickly in line with the expansion of urban commerce.

- Industrial Construction

Due to its structural strength and adaptability, precast concrete is frequently utilized in industrial structures like factories, warehouses, and logistics hubs. Supply chain infrastructure development, e-commerce growth, and manufacturing expansion are all strongly correlated with demand. With the help of increased logistics networks and industrial modernization, Asia Pacific leads this market, followed by North America.

- Infrastructure

The largest and most reliable end-use category is infrastructure, which includes utility systems, roads, railroads, bridges, and airports. Precast systems provide less traffic disturbance, durability, and shorter building times. While North America and Europe concentrate on rehabilitation and improvement projects, there is strong demand in Asia Pacific, the Middle East and Africa, and South America due to public infrastructure spending.

- Institutional

For effectiveness and long-term durability, precast concrete is being used more and more in institutional buildings, including public facilities, government buildings, universities, and schools. Standardized building regulations and investments from the public sector boost this area. While rising nations in Asia Pacific and Africa are propelling fresh growth through the expansion of healthcare and educational facilities, adoption in Europe and North America is constant.

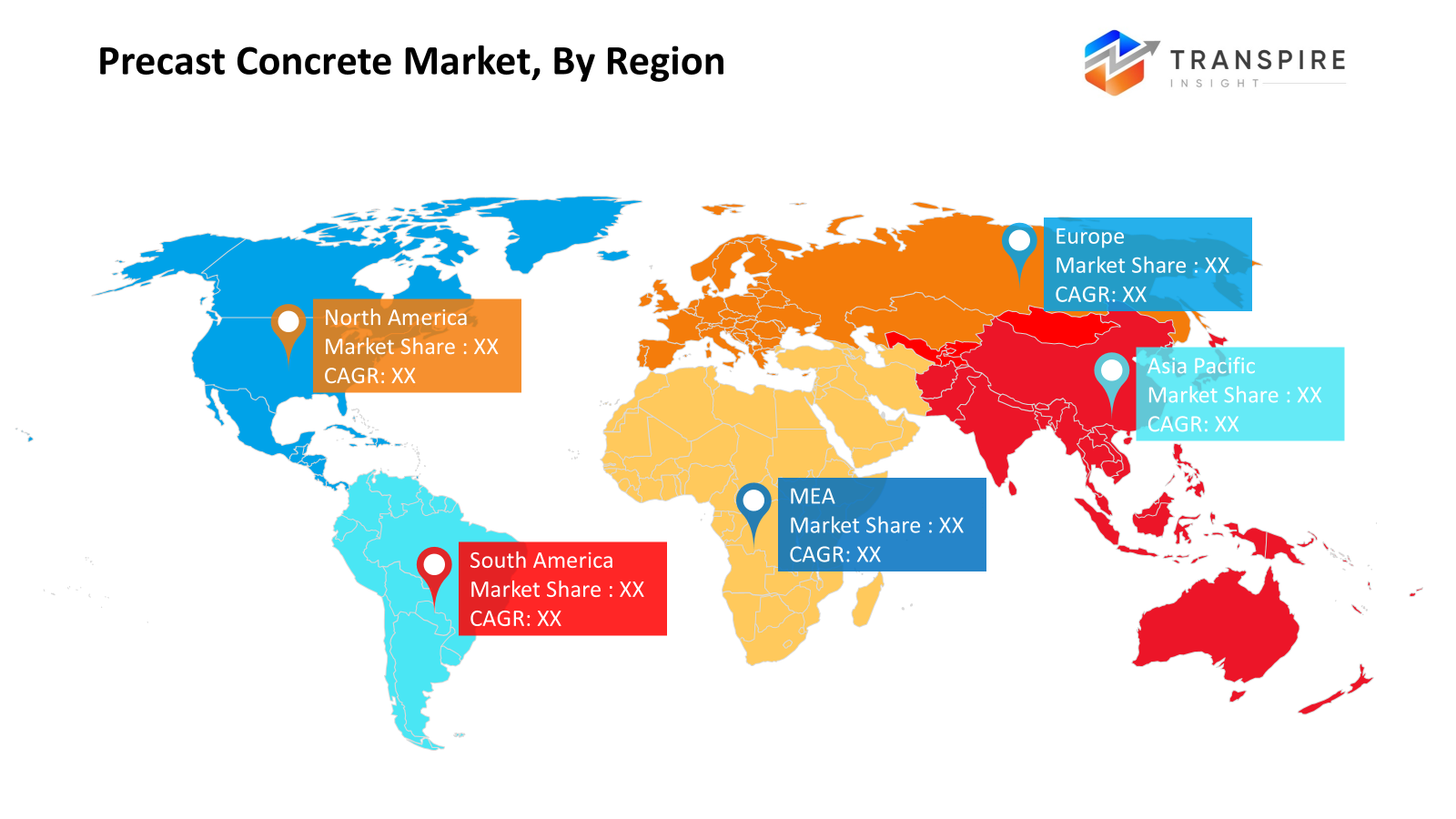

Regional Insights

North America, which includes the US, Canada, and Mexico, is a developed market that is bolstered by industrial development, commercial redevelopment, and infrastructure restoration. While Canada places a strong emphasis on sustainable building methods and Mexico gains from the expansion of industrial corridors, the United States dominates regional demand. While Tier 2 regions concentrate on cost-effective applications, Tier 1 markets lead in the adoption of advanced precast. Energy-efficient building regulations and urban renewal initiatives are driving high demand throughout Europe, including Germany, the UK, France, Spain, Italy, and the rest of the continent. While Southern European nations exhibit growing acceptance in infrastructure and residential buildings, Germany and the UK lead the world in the use of precast in structural and architectural projects. The fastest-growing geographical market is Asia Pacific, which includes China, Japan, Australia and New Zealand, South Korea, India, and the rest of Asia Pacific. Due to urban housing and infrastructure projects, China and India have the largest volume demand, whereas South Korea and Japan concentrate on high-performance and seismically resistant precast systems.

South America, which is led by Brazil and Argentina, is growing steadily because to the region's transportation system and need for urban housing. Mega infrastructure projects, smart city initiatives, and institutional construction investments benefit the Middle East and Africa, which includes Saudi Arabia, the United Arab Emirates, South Africa, and other regional markets.

To learn more about this report, Download Free Sample Report

Recent Development News

- January 2026, Fabcon unveiled its next-generation VersaCore Pro precast wall technology, which is designed to speed up construction deadlines with enhanced performance, reduced weight, increased durability, and simpler production. This shows how Fabcon has responded to changing consumer demands for more effective and efficient products.

- In March 2025, ModCorr established ModCorr PreCast, a new division devoted to producing high-performance precast concrete cells, following the acquisition of American Correctional Maintenance's (ACM) PreCast Division. This strategic expansion strengthens its delivery capabilities and product focus.

|

Report Metrics |

Details |

|

Market size value in 2025 |

USD 132.0 Billion |

|

Market size value in 2026 |

USD 140.0 Billion |

|

Revenue forecast in 2033 |

USD 240.0 Billion |

|

Growth rate |

CAGR of 8.00% from 2026 to 2033 |

|

Base year |

2025 |

|

Historical data |

2021 – 2024 |

|

Forecast period |

2026 – 2033 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

United States; Canada; Mexico; United Kingdom; Germany; France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Argentina; South Africa; Saudi Arabia; United Arab Emirates |

|

Key company profiled |

Boral Limited, CRH Plc, CEMEX S.A.B. de C.V., Forterra, Inc., Vigier Beton SA, Bouygues Construction, Lehigh Hanson, Inc., LafargeHolcim Ltd., BASF SE, Larsen & Toubro Ltd., Tindall Corporation, Balfour Beatty Plc, Olson Precast Company, Spancrete Manufacturing, LLC, Gulf Precast Concrete Co. LLC |

|

Customization scope |

Free report customization (country, regional & segment scope). Avail customized purchase options to meet your exact research needs. |

|

Report Segmentation |

By Product Type (Columns & Beams, Girders, Slabs & Floors, Walls & Panels, Pipes & Culverts, Paving Slabs, Staircases, Others), By Construction Type (Elemental / Component Systems, Modular Construction Systems) and By End Use (Residential Construction, Commercial Construction,Industrial Construction, Infrastructure, Institutional) |

Key Precast Concrete Company Insights

LafargeHolcim Ltd. is a well-known worldwide supplier of precast concrete solutions. It serves the residential, commercial, and infrastructure sectors by utilizing its large presence and vertically integrated supply chain. In the face of stricter environmental laws, the company's strategic investments in low-carbon concrete technologies and sustainable construction materials bolster its value proposition. In addition to increasing regional production capacity, LafargeHolcim's recent acquisitions, like Alkern in France, improve its precast range for industrial and infrastructure applications. It has an advantage over rivals in important global markets thanks to its focus on digital design, modular building methods, and regional production facilities.

Key Precast Concrete Companies:

- Boral Limited

- CRH Plc

- CEMEX S.A.B. de C.V.

- Forterra, Inc.

- Vigier Beton SA

- Bouygues Construction

- Lehigh Hanson, Inc.

- LafargeHolcim Ltd.

- BASF SE

- Larsen & Toubro Ltd.

- Tindall Corporation

- Balfour Beatty Plc

- Olson Precast Company

- Spancrete Manufacturing, LLC

- Gulf Precast Concrete Co. LLC

Global Precast Concrete Market Report Segmentation

By Product Type

- Columns & Beams

- Girders

- Slabs & Floors

- Walls & Panels

- Pipes & Culverts

- Paving Slabs

- Staircases

- Others

By Construction Type

- Elemental / Component Systems

- Modular Construction Systems

By End‑Use

- Residential Construction

- Commercial Construction

- Industrial Construction

- Infrastructure

- Institutional

Regional Outlook

- North America

- United States

- Canada

- Mexico

- Europe

- Germany

- United Kingdom

- France

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- Japan

- China

- Australia & New Zealand

- South Korea

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- United Arab Emirates

- South Africa

- Rest of the Middle East & Africa

APAC:+91 7666513636

APAC:+91 7666513636