Jan 19, 2026

The report “Modular Construction” Market By Type (Relocatable, Permanent), By Material (Wood, Steel, Concrete, Others), By Application (Residential, Commercial, Industrial, Healthcare, Educational), By Module (Four-sided, Open-sided, Partially open-sided, Mixed modules & floor cassettes, Modules supported by a primary structure, Others)” is expected to reach USD 15.58 billion by 2033, registering a CAGR of 31.10% from 2026 to 2033, according to a new report by Transpire Insight.

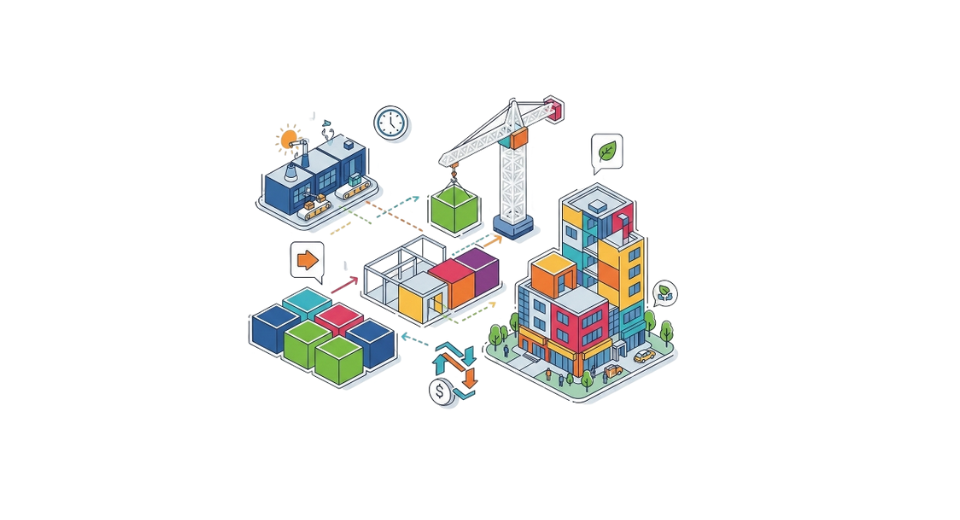

The modular construction market has emerged as a revolutionizing factor that positively impacts the built environment by curtailing construction timelines, improving resource efficiency, and ensuring efficient quality control. Modular construction entails the prefabrication of standardized volumetric and panelized components within controlled environments, such as factories, and assemblages on final construction sites for completed projects. This construction method less depends on conventional site-specific construction practices, which were not only prone to delays but also posed risks to construction personnel and resulted in poorer quality outcomes. Increased demand for various construction solutions, including affordable housing, has propelled the adoption of modular construction from niche solutions to strategic alternatives for developers, governments, and institutions. There has been an increasing demand for modular construction based on different application markets, such as residential, healthcare, commercial buildings, and educational infrastructure. In the residential market, developers are increasingly using modular solutions to counter the problem of cost escalation and to provide better energy efficiencies to the homes. In healthcare, the application of the modular approach is increasing as it enables the quick expansion of capacities based on the variable demand due to health emergencies. Commercial and institutional customers find the modular approach to construction helpful as it ensures timely delivery without compromising on design.

Government assistance and regulatory support offered in developed and developing nations are accelerating investments in modular infrastructure. With all parties involved opting for flexible construction solutions that ensure quick returns on investment, the modular construction industry soon finds itself set for great advances in all global locations.

The Relocatable segment is projected to witness the highest CAGR in the Modular Construction during the forecast period.

According to Transpire Insight, Relocatable modular construction has recently become an essential response to circumstances that call for rapid deployment and agility in projects. Permanent versus relocatable modules differ in that the former are more complex and less suited for relocation, while the latter are more straightforward and amenable to relocation. The need for relocatable modules has manifested in transient types of construction, such as offices for construction projects, temporary education facilities, emergency housing, and event space. The adaptability to optimize an existing building system according to changing needs has become more desirable for public and private sectors.

Relocatable modules minimize the time required for rapid site preparation, providing deployable facilities faster than conventional construction and at fixed costs. Another benefit offered by the system is improving the efficiency of space utilization, which allows buildings to be relocated from place to place. This remains beneficial for growing companies with changing space requirements.

The Steel segment is projected to witness the highest CAGR in the Modular Construction during the forecast period.

Steel has come to be preferred in modular construction because of its inherent strength, stability, and versatility to be reused. The strength of steel modular systems far exceeds that of their counterparts in terms of spanning and handling heavier loads. This makes modular steel construction superior to others in multi-story buildings, offices, and industrial structures. Moreover, fabrication in a controlled environment produces more consistent and desired results compared to welding or cutting in the open, which are prone to defects. This versatility in designing additional to steel's amenability to modern manufacturing and other materials, such as insulated panels and glazing, has made modular steel construction more attractive and desirable in terms of a balance between performance, rapid delivery, and total cost of ownership.

The use of steel can be closely associated with the sustainability goals that exist in the construction industry. It is widely recyclable, where some of the manufacturers use recycled materials without affecting the strength and properties.

The Residential Enterprises segment is projected to witness the highest CAGR in the Modular Construction during the forecast period.

According to Transpire Insight, The effect of modular construction on residential construction can be viewed in terms of its ability to provide a solution that fits all criteria related to affordability, quality, and quick implementation within a rapidly decreasing market for apartments and homes. For conventional construction, weather conditions, lack of personnel, and supply chain issues have been known to pose challenges that slow down construction timelines and increase costs significantly, unlike modular construction, where most challenges for conventional construction can be avoided by implementing large scales of construction in controlled environments within factories and factories and factories. Many developers and real estate companies have turned to these solutions as a way to counteract deficits in affordable homes within most suburban and metropolitan areas where quick and quality homes can help meet these deficits.

Consumers can also benefit from the precision and personalization involved in modular residential products. Modern factory-built modules can feature sophisticated energy-saving systems, up-to-date materials, and flexible layouts that would be the equal of traditional construction in terms of aesthetics and functionality.

The IT & Telecommunications segment is projected to witness the highest CAGR in the Modular Construction during the forecast period.

Four-sided modules completely closed volumetric modules prefabricated off-site are the most popular solution in modular construction because of the relative simplicity of their scaling and handling. Four-sided modules are self-contained during transport and assemblage, which is a definite bonus in terms of construction complexity. Four-sided modules are most applicable in dwelling and office buildings, in which the entirety of the internal space – a bathroom, a living room, for example is prefabricated with completed MEP installations.

This modularity makes it easier to incorporate flexible architecture, allowing for the arrangement of the modules to form complex structures through stacking, lining up, and connecting them. The most preferred form of modularity among the developers of residential high-rises, hotels, and institutional structures includes the four-sided modularity of the module. This modularity allows the module to maintain its architecture while minimizing the potential for defects. Recent developments within the realm of the logistics of transporting these structures further help the application of the four-sided modularity of the module..

The North America region is projected to witness the highest CAGR in the Modular Construction during the forecast period.

The pace of adoption of modular construction technology is dominated by North America, with a robust combination of demographic, economic, and regulatory factors at play. More specifically, off-site modular construction is seen as a way for those with a need for construction projects to achieve acceleration and cost control with greater predictability, especially amid a construction labor shortage of significant proportions presently experienced by the United States of America, for instance. At the same time, strict construction and energy performance standards presently observed by various states have contributed towards a critical adoption of high-quality off-site construction with an emphasis on high energy performance requirements that are more reliably met using off-site construction technology presently compared to conventional construction technology. Canada is complementing the trend with specific strategies focused on supporting modular construction and infrastructure projects as part of broader country and provincial strategies to overcome housing shortages and productivity in construction. Modular construction is also on the rise in the major metropolitan areas as the cost of land and labor continues to make traditional construction methods even more challenging. Modular construction is being adapted in the institutional sectors such as hospitals and education institutions to increase capacities rapidly without compromising on stringent safety and performance criteria. The region's infrastructure ecosystem, technological preparedness, and favorable policies make North America an attractive destination and sustains leadership in the global landscape in terms of technological advancements in modular construction.

Key Players

The top 15 players in the Modular Construction market include Sekisui House Ltd., Laing O’Rourke, Red Sea International, Skanska AB, Bouygues Construction, Premier Modular Limited, KLEUSBERG GmbH & Co. KG, CIMC Modular Building Systems Holdings Co., Ltd., DuBox, Wernick Group, Lendlease Corporation, Modulaire Group, Guerdon, LLC, Hickory Group, and ATCO Ltd.

Drop us an email at:

Call us on:

+91 7666513636