Feb 16, 2026

The report “Resinous Flooring Market By Resin Type (Epoxy, Polyurethane (PU), Methyl Methacrylate (MMA), Polyester, Acrylic, Others), By Flooring System (Self-Leveling Systems, Broadcast Systems, Mortar Systems, Coating Systems, Trowel-Applied Systems), By Application (Industrial Flooring, Commercial Flooring, Residential Flooring) and By End-Use Industry (Manufacturing, Food & Beverage, Healthcare & Pharmaceuticals, Automotive, Chemical & Petrochemical, Warehousing & Logistics, Retail & Commercial Spaces, Others)” is expected to reach USD 13.80 billion by 2033, registering a CAGR of 8.90% from 2026 to 2033, according to a new report by Transpire Insight.

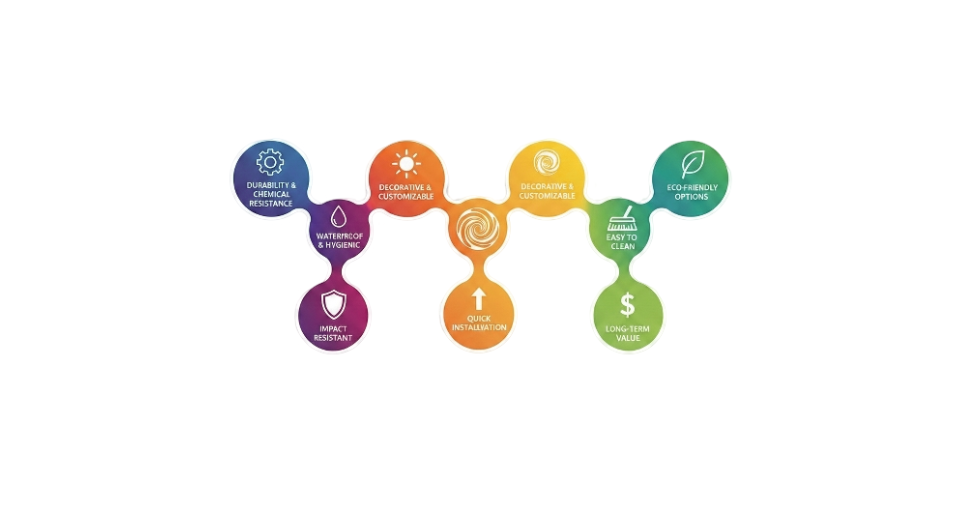

The market for resinous flooring continues to experience a steady growth rate due to the increasing demand for high-performance flooring solutions in various sectors including industry, commerce, and institutions. The demand for resinous flooring systems, such as epoxy, polyurethane and MMA-based flooring, is increasing significantly due to their high-performance characteristics such as durability, resistance to chemicals, and seamless finish. Sectors that require high standards of hygiene and safety, such as the food industry, healthcare, and manufacturing, are also contributing to the growth of this market. The market growth for resinous flooring is also driven by the increasing construction activities and renovation projects in developed countries. The old industrial buildings that require renovation to improve their operating efficiency and meet the requirements of various regulations are also contributing to the growth of this market. The resinous flooring market also benefits from the cost advantages that this type of flooring offers, which include lower maintenance costs and a longer lifespan making it a popular choice for large-scale buildings.

The market growth for resinous flooring can be attributed to the technological advancements that have improved the efficiency and environmental acceptability of resinous flooring systems, particularly those that offer rapid curing and low VOC characteristics. The demand pattern is changing as end users are increasingly looking for safe, attractive, and non-intermittent products. Seamless flooring products are reducing contamination hazards and improving workplace safety. The expansion of commercial infrastructure, such as retail outlets, healthcare facilities, and logistics infrastructure, is generating more demand. The growing awareness of sustainability and green building products is also impacting demand globally. The growing economies are contributing to high growth rates, especially from industrialization and urbanization. Investments in industrial infrastructure, warehousing, and commercial infrastructure development are expanding the market. Manufacturers are concentrating on developing innovative products to provide customized flooring solutions to meet different performance requirements, thereby boosting competitive activity.

The Epoxy segment is projected to witness the highest CAGR in the Resinous Flooring during the forecast period.

According to Transpire Insight, The epoxy resin segment continues to dominate the market due to the inherent advantages that include good adhesion, mechanical properties, and cost-effectiveness compared to other available materials. The epoxy flooring systems offer good resistance to abrasion, chemicals, and heavy loads, making them suitable for industrial and commercial applications where product durability is a key concern. Moreover, this segment benefits from the wide scope of applications in various manufacturing facilities, warehouses, and healthcare institutions, where seamless and easy-to-maintain surfaces are necessary to support facility operations and product requirements.

Epoxy flooring systems also offer flexibility in product formulation to accommodate various properties that can be achieved to meet the needs of the final users, including slip resistance, electrical conductivity, and appearance. The continuous innovation in the formulation of new epoxies that offer low emission and rapid curing characteristics will support the expansion of applications in renovation projects where downtime must be minimized. The reliability and price competitiveness of these products will continue to sustain the dominance of this segment in the resinous flooring market.

The Self-Leveling Systems segment is projected to witness the highest CAGR in the Resinous Flooring during the forecast period.

Self-Leveling Flooring Systems is the leading type of flooring systems due to the ability of these systems to deliver smooth and seamless surfaces that are ideal for sensitive applications. These systems have found extensive use in healthcare facilities and laboratories due to the importance of cleanliness and uniformity of the surfaces. Additionally, the ease of use and the ability to correct irregularities in the substrate have made the systems more popular, particularly in renovation applications that require efficient construction time.

The segment is also driven by the increasing need for aesthetically pleasing flooring systems that deliver performance. Self-Leveling Flooring Systems deliver improved durability and ease of maintenance, which is important for applications in high-traffic areas. As the construction of commercial and institutional facilities continues to rise globally, the need for aesthetically pleasing flooring systems is expected to propel the growth of the segment.

The Industrial Flooring segment is projected to witness the highest CAGR in the Resinous Flooring during the forecast period.

According to Transpire Insight, The market for industrial flooring continues to hold the largest share in terms of application due to the rising demand for superior flooring surfaces that can withstand heavy mechanical as well as chemical stress. The expansion of manufacturing facilities, automation of warehouses, and construction of logistics infrastructure are creating a demand for flooring solutions that ensure uninterrupted facility operation as well as worker safety. Resinous flooring solutions ensure seamless flooring surfaces that minimize downtime as well as maximize the longevity of the flooring surface in harsh working conditions.

In addition, there is a rising demand among industrial facility operators to ensure safety compliance as well as cost efficiency in flooring solutions. Resinous flooring solutions minimize surface damage as well as contamination risks in industries such as automotive manufacturing, food processing, as well as chemical manufacturing. As industrial facilities continue to expand in terms of capacity as well as upgrade their infrastructure, the market for industrial flooring applications is expected to retain its leading position in terms of market demand.

The Manufacturing segment is projected to witness the highest CAGR in the Resinous Flooring during the forecast period.

Manufacturing continues to hold the leading position in the end-use industry segment, considering the need for flooring solutions that can withstand constant activity and movement of heavy machinery. Resinous flooring solutions ensure protection from chemicals, abrasion, and impact, which is vital for ensuring the reliability of flooring in these establishments. The growing trend of incorporating automation in these establishments also increases the demand for flooring solutions that ensure smoother surfaces.

The growing concern for workplace safety in the manufacturing industry also increases the demand for high-performance flooring solutions. Resinous flooring solutions ensure better visibility, slip resistance, and easy maintenance, which makes them more suitable for the industry. The growing investments in infrastructure development in both developed and emerging economies continue to reinforce the dominance of the manufacturing industry in the resinous flooring market.

The North America region is projected to witness the highest CAGR in the Resinous Flooring during the forecast period.

North America is one of the most mature markets for resinous flooring, with high industrial standards, commercial construction, and regulatory requirements. The United States is the major contributor to the region's revenue generation, with strong industrial, warehousing, and healthcare sectors requiring high-quality flooring solutions. Similarly, Canada and Mexico also play their roles in the North American region, focusing on industrial upgrades, warehousing, and commercial renovation projects.

The North American region has a strong market for epoxy, polyurethane, and self-leveling flooring systems, which are increasingly being used due to their long lifespan, high chemical resistance, and low maintenance requirements. Flooring renovation projects are also adding to the growth of the resinous flooring industry, particularly for rapid-curing and low-VOC systems. The region also focuses on safety, hygiene, and operational efficiency, especially for industries such as food processing, pharmaceutical, and automotive. Technological advancements, along with an established contractor base and availability of high-quality resin flooring solutions, make North America one of the most prominent markets for resinous flooring.

Key Players

The top 15 players in the Resinous Flooring market include Sika AG, BASF SE, RPM International Inc., The Sherwin-Williams Company, PPG Industries, Inc., Flowcrete Group Ltd., Stonhard, Ardex Group, Mapei S.p.A., Fosroc International Ltd., Laticrete International, Inc., AkzoNobel N.V., RESDEV, ArmorPoxy, and CEMENTOS CAPA, S.L.

Drop us an email at:

Call us on:

+91 7666513636